Geoscience Reference

In-Depth Information

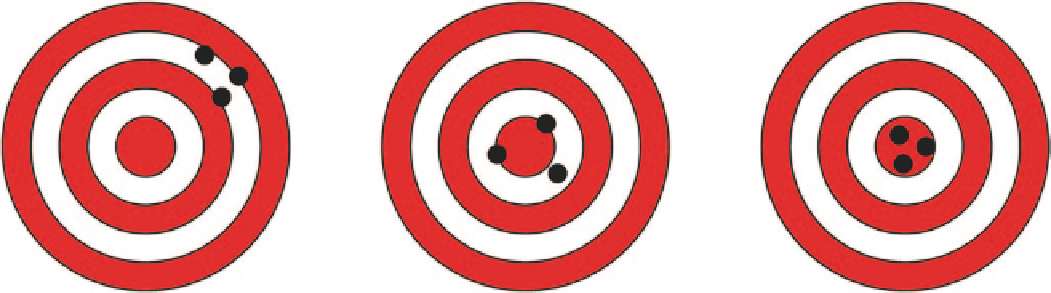

Fig. 5.7

Accuracy and precision.

Left

is precise but inaccurate;

center

is accurate but imprecise; and

right

is both precise and accurate

re-assay them. In this case, failed check samples trigger cor-

rective measures for future assaying.

The sampling QA/QC program should cover (a) sampling

conditions in the field; (b) sample preparation; (c) analytical

accuracy and precision; and (d) correctness of the laboratory

reports and transfer of the information to the database(s).

The materials to be used in the QA/QC program include (a)

standards, or reference material; (b) blanks, which are samples

with no grade; (c) field duplicates, taken at the drill hole site or

core box; (d) coarse duplicates, taken as the first reject at the

sample preparation stage, typically −10 mesh in size; and (e)

pulp duplicates, which are taken from the last size-reduction

and splitting at the end of the sample preparation process.

There are generally two or more laboratories involved that

would include a primary or principal laboratory for routine

work, and a secondary or check laboratory. Occasionally, a

referee laboratory is needed when discrepancies between the

primary and secondary laboratories cannot to be resolved.

Sampling and assaying protocols are established prior to

processing the samples from the field. These protocols should

cover all aspects of sample processing and handling including

chain of custody. The sampling theory originally developed

by P. Gy (

1982

) can be used to determine optimum sample

preparation protocol, such that errors introduced in the prepa-

ration and assaying procedures are minimized (see above).

The sample preparation and assaying protocols should

be identical for the primary and secondary laboratory. The

mining company should have a staff person in charge of the

overall QA/QC program whose duties include ensuring that

the protocols used at the different labs are consistent. That

person should inspect the facilities on a regular basis.

handling of the samples. There should be both pulp and

coarse blanks prepared and inserted into the sample prepara-

tion stream. In the case of core samples, the coarse blank

is introduced after the first crushing stage, while the pulp

blank should be inserted as a separate envelope in the sample

batch.

It is advisable that the blank have the same matrix (min-

eralogy) and result in a pulp with the same characteristics

as the main samples so it is not obvious to the laboratory

that the sample is different in any way. This is sometimes

difficult to achieve, although at least the main characteris-

tics such as color should be as similar as possible. Very low

grade samples should not be used as proxies for blanks.

5.4.2.2 Standards

Standards are samples for which its grade is known within a

certain precision. They are used to check the accuracy of the

analytical laboratories, by comparison of the re-assays to the

reference value.

There are commercial standards that can be purchased.

They provide samples with known grades for some types of

ore deposits. This material can be purchased from labora-

tories and institutions around the world. The standards are

delivered with certificates stating the accepted value and its

precision, in addition to a full description of the procedures

used to analyze them.

Alternatively, the mining company has the option of

developing its own standards. The material used to obtain

the standard is typically from the same deposit as the main

sample stream, which ensures that differences in the sample

matrices will be minimal. The certification of standards re-

quires major analytical work, which can be done through a

round robin analysis using no less than 6 laboratories, and

more commonly 8. This work can be managed by the mining

company or outsourced to an external analytical laboratory,

which would also be part of the round robin laboratories,

and would provide the final certification for the samples and

their corresponding tolerance limits.

5.4.2

Elements of a QA/QC Program

5.4.2.1 Blanks

Blanks are samples with no grade of interest whose purpose

is to check laboratory contamination and to verify correct