Geoscience Reference

In-Depth Information

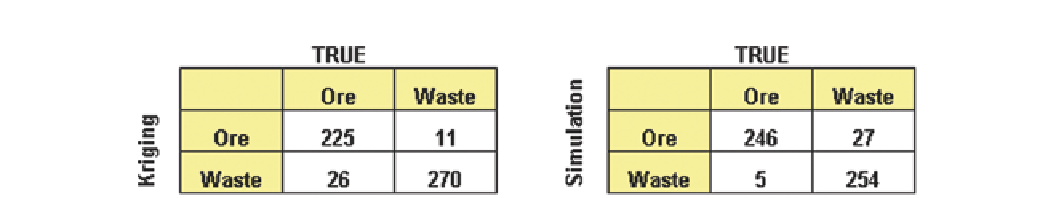

Table 14.18

Ore/waste classification summary of kriging (left) and simulation (right) relative to true ore/waste classification

pared with the true profit of $ 7.89 M. The results from such

a comparison showed that the simulation approach yielded

$ 7.28 M while kriging yielded $ 7.06 M in profit. Although

these profit values appear high for the relatively small area

of a single bench, the relative percentage increase in profit is

the key result. Multivariate simulation resulted in 92 % of the

true profit relative to the 89 % yielded by kriging. In practice,

this 3 % difference may translate to several millions of dol-

lars in increased profit if a larger area and multiple benches

are considered.

Conventional Gaussian cosimulation approaches are suf-

ficient for straightforward multivariate problems; however,

for the complexity of the Red Dog deposit, these common

approaches are inadequate. The availability of multiple

metal grades within multiple domains warrants some con-

sideration of the relationship between these grades, and how

these relationships change from one rock type to the next.

The approach shown here was designed to explicitly address

this key issue. Consequently, the resulting models not only

reproduce the univariate data and its spatial variability, but

taken together, they also honour the multivariate relations

between the different metals/minerals within the different

domains.

vals that result from the simulation model. Resource clas-

sification is an exercise intended for public disclosure and

thus considers large volumes. It is global in nature. They

should not be used to provide a technical answer on a local

scale, such as risk assessment of mine schedules. This case

study considers two different mining methods (open pit and

underground), which implies that recoverable reserves are

assessed based on different Selective Mining Units (SMUs).

Probability intervals derived for these different SMUs are

contrasted to the uncertainty model developed from the clas-

sification scheme used by the operation to report resources

and reserves. The study assesses the risk of not achieving

predicted tonnages and grades within a mine plan, which is

based on selecting measured and indicated blocks only.

There are several aspects of resource classification

schemes that should be emphasized to better understand the

motivation for this case study:

1. Resource classification is intended to provide some mea-

sure of the degree of confidence in the resource state-

ments. In this sense, it is a global uncertainty model. The

same can be obtained deriving probability intervals from

the conditional simulation models.

2. Internally, mining companies sometimes misuse resource

classifications as risk assessment tools, although the

manner in which this is done varies widely among geolo-

gists, mine planners, and mine management. This stems

from the temptation to use resource classification codes

on a block by block basis, or at a more local scale than

warranted.

3. Despite the existence of codes and guidelines that may

give the appearance of objectivity to the process of re-

source classification, Competent Persons would use dif-

ferent resource classification schemes for any given de-

posit. Management's perception of risk is likely to be dif-

ferent. Technical personnel will generally disagree about

the application of the Resource Classification scheme

used, and how to inject the different levels of confidence

into the mine plan and projected cash flow.

This general lack of understanding of the purpose and mean-

ing of resource classification schemes can be mitigated by

using a geostatistical model of uncertainty. Although they

are not objective, a more detailed description of the pre-

dicted uncertainty for each particular block, phase, zone, or

14.5

Uncertainty Models and Resource

Classification: The Michilla Mine

Case Study

Geostatistical simulation provides a model of uncertainty at

different stages of a mining project and for different types

of risk assessment. Simulation has been used for grade con-

trol in daily operations, to assess the uncertainty of minable

reserves at the project's feasibility stage, and to assess min-

eralization potential in certain settings. Other applications

include assessment of recoverable reserves, resource and re-

serve classification, and drill hole spacing optimization stud-

ies. All large-scale applications of conditional simulations

intend to benefit from a model of uncertainty that describes

the variability observed in the data and its impact on the pro-

cess assessed.

In this case study, a resource classification derived through

more conventional methods is compared to probability inter-