Geoscience Reference

In-Depth Information

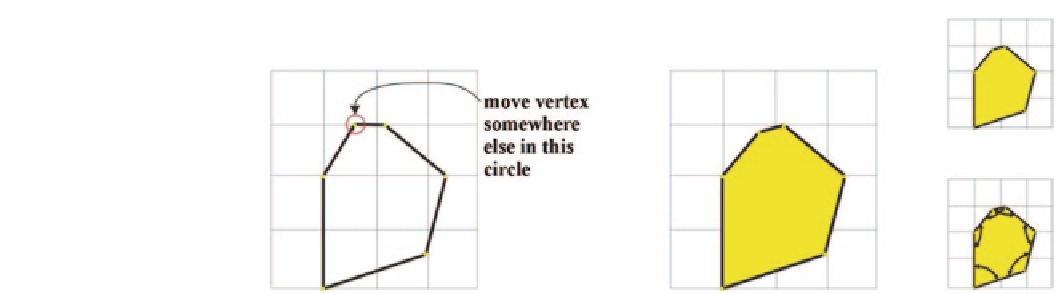

Fig. 13.12

A vertex is randomly

selected and moved, a new shape

obtained and new profit and

penalties obtained

week of work. The ore/waste selection process will normally

be based on a conventional method, perhaps some form of

Kriging duly restricted with geology. Blast hole sampling

should routinely provide acceptable samples for ore/waste

selection. Information from relevant prior blasts should

be used in defining current dig lines. Geologic mapping

should aid in the daily task of defining the dig lines, which

is generally a manual operation. Proper material accounting,

reconciliation procedures, and constant presence and con-

trol by the mine geologist in the field should minimize the

probability of making gross mistakes.

Good practice of medium- and short-term modeling

requires a well defined and consistent methodology for up-

dating the resource model, satisfying both the needs of short-

term mine planning department and the short-term prediction

of metallurgical performance. A sufficiently detailed study

would have determined all the important implementation

parameters and methodological details, including the proce-

dures required to update the geologic model. The short-term

models should be produced at regular time intervals, be al-

ways reconciled with recent past production, and compared

against the original long-term resource model for the same

areas. The model updating process should be semi-automat-

ic, although always fully validated. Good practice in ore/

waste selection requires the recognition of the limitation

of selecting on grade, and therefore the use of an optimal

selection method, with consideration of the basic economic

parameters. Dig lines are usually hand drawn, and control

and accounting procedures are strict. Reconciliation is usu-

ally kept on a blast-by-blast basis, and reported monthly.

Best practice in medium- and short-term modeling, in ad-

dition to the above, involves using conditional simulation

models to provide for the uncertainty model and the risk as-

sessment that short-term mine planners need. Other aspects

of the model updating should be similar to what is defined

as good practice, but the models are more likely to be sim-

ulation models. Similarly, the ore/waste selection should

have been fully optimized, including the possibility of

automatically drawing dig lines on a daily basis. In all cases,

reconciliation procedures should be in place, and should be

used to feed back and maintain an optimum implementation

of the method as mine conditions change.

In addition, best practice in long- and medium-term mod-

eling involves the development of dynamic models, which

are constantly updated, not only in terms of grade estimation,

but most importantly in terms of the geologic model. Pro-

duction data and infill drilling are used with production map-

ping (drift or bench) to update on a regular basis portions of

the long-term model that is therefore constantly up to date.

It amounts to merging the medium and long-term model into

a single model, updated, for example, on a monthly basis.

13.7

Exercises

The objective of this exercise is to review some concepts

related to grade control. Some specific (geo)statistical soft-

ware may be required. The functionality may be available

in different public domain or commercial software. Please

acquire the required software before beginning the exercise.

The data files are available for download from the author's

website—a search engine will reveal the location.

Consider the molybdenum data in

bh-data.dat

. You

will be asked to conduct a full geostatistical study from his-

tograms through simulation. The exercise will go quickly be-

cause the data are closely spaced and reasonably well behaved.

Question 1:

Plot a location map and histogram of the Mo

data. Comment on the spacing of the data. Your

inal estimation/simulation model should be at

a spacing of about 1/3 to 1/2 of the blasthole

spacing. We will not consider any volume aver-

aging in the simulation. Decluster the data if

you consider it necessary.

Question 2:

Calculate and it the variograms of the molyb-

denum grade and estimate a model with ordi-

nary kriging. Perform cross validation if time

permits and ensure that no conditional bias

exists in the estimates.

Question 3:

Calculate and it the variograms of the normal

scores transforms of molybdenum.