Environmental Engineering Reference

In-Depth Information

Wind Generator

Li-Polymer

Battery

Eco

Sensor Node

Solar Panel

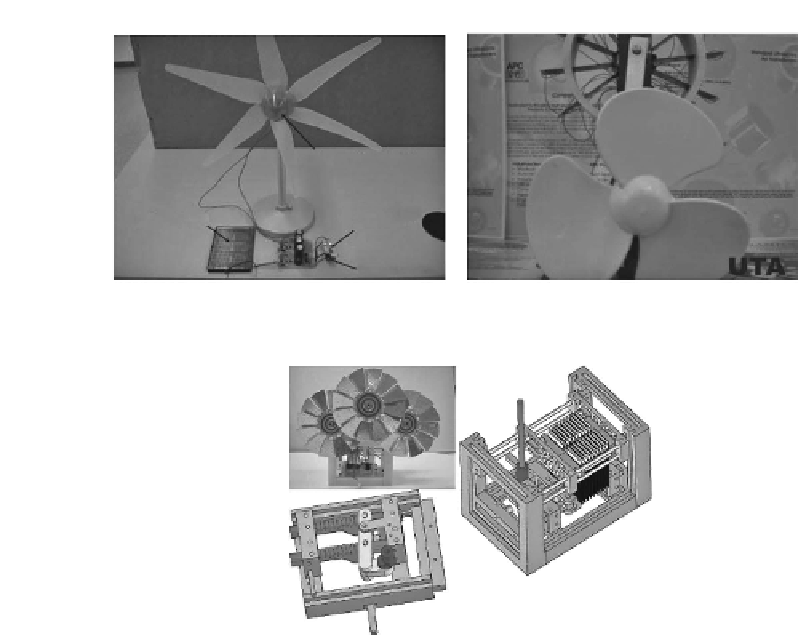

(a) AmbiMax hardware with a solar panel,

wind generator, lithium polymer battery,

and Eco Node

(b) Piezoelectric windmill prototype

(c) Optimized design of the small-scale windmill with an isometric view

and internal crankshaft structure exhibiting the translation mechanism

FIGURE 1.20

Examples of TEH systems.

Weimer et al. [60] presented an anemometer-based solution to perform the

WEH and sensing tasks, which are accomplished separately by two different

devices. The authors utilize the motion of the anemometer shaft to turn a

coupled alternator to generate electrical power for the sensor nodes. Although

the sensor nodes incorporating the harvesting solution have an increased

operational lifetime, this comes with the price of larger device size, higher

overall cost, and higher energy conversion loss.

In another WEH research work [61], Priya et al. designed a windmill that

uses piezoelectric elements to generate electricity from wind energy (see

Figure 1.20b

). An output power of 10.3 mW was harvested and reported

for a wind flow that leads to 6 rotations per minute. Subsequently, another

group of researchers, Myers et al. [62], developed an optimized small-scale

piezoelectric windmill as shown in

Figure 1.20c

. The whole structure of the

windmill is made of plastic, and it utilizes 18 piezoelectric bimorphs to con-

vert wind energy, hence vibration energy, into electrical energy. The windmill

was tested to provide 5 mW of continuous power at an average wind speed of

Search WWH ::

Custom Search