Environmental Engineering Reference

In-Depth Information

Current Carrying

Conductor of

1-4 A

r

b

= 0.5 cm

r

a

= 1.5 cm

Magnetic

Field Lines

Ferro-Magnetic

Material Coiled

with Copper Wires

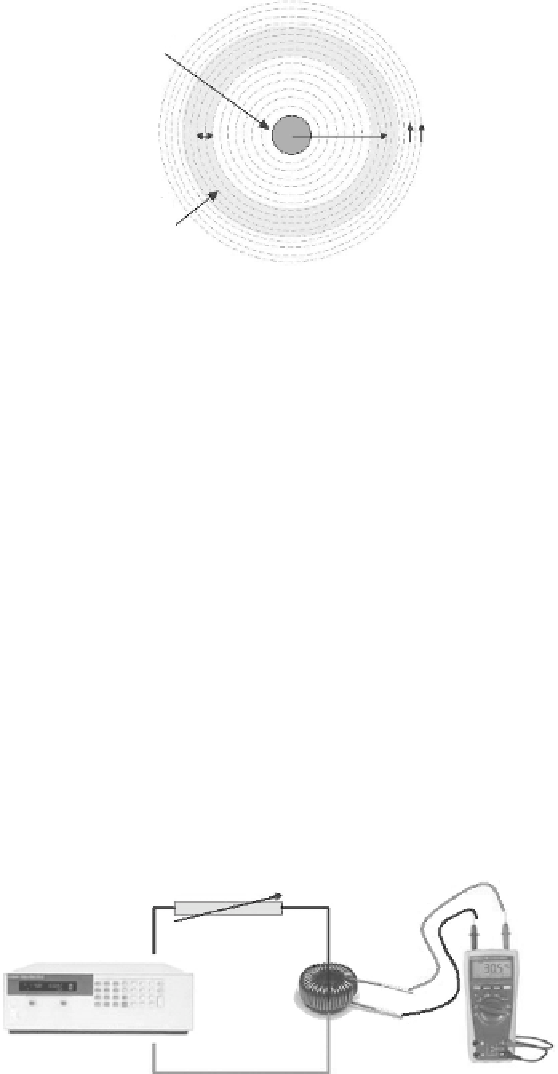

FIGURE 6.3

To p view of ferrite core with current carrying conductor.

to the magnetic field

B,

the loop area

A,

the winding number of turns

N,

and

the frequency of the current

f

.

The experimental setup to measure the induced voltage

V

emf

[

=

NB

t

) where the negative sign is due to Lenz's law] from the toroid-based

magnetic energy harvester via the current-carrying power cable is shown in

Figure 6.4

. The current flowing in the circuit varies from 1 to 4 A by adjusting

the voltage knob of the AC power supply. Due to the high current along the

circuitry, the high-wattage resistor load bank is utilized. A summary of the

measured and calculated induced emf (electromotive force) voltage for dif-

ference current flowing in the primary side power line is presented in

Table

6.1

.

It can be observed from

Table 6.1

that as the current flowing in the main-

stream power line increased from 1 to 4 A, the magnetic field

B

obtainable

at 1.5 cm away from the centre of the conductor also increased from 0.02 to

0.08 T. For that reason, the induced voltage generated at the output of the

toroid magnetic energy harvester was increased. During the characterization

process, the

r

a

distance of 1.5 cm was set as the reference point based on the

practical considerations of the physical diameter of the power cables and the

space taken by 500 turns of copper winding.

As i n

(

Resistor Load Bank

To r oid

AC Power Supply

Digital Multimeter

FIGURE 6.4

Characterization of a magnetic energy harvester based on Faraday's law.

Search WWH ::

Custom Search