Environmental Engineering Reference

In-Depth Information

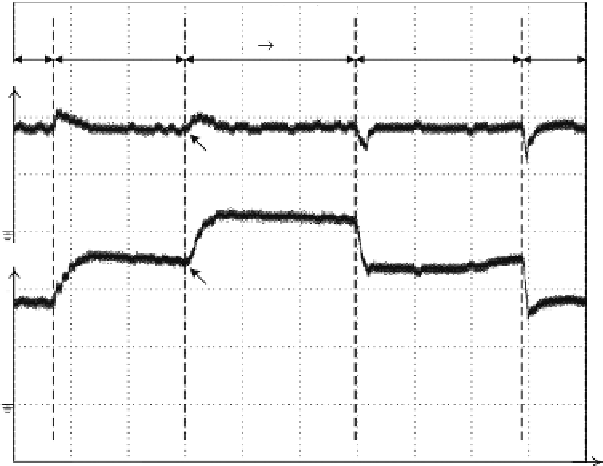

Main :125 k

10 s/div

∆T

10 K

∆T 10 K,

380 lux

∆T 10 K,

380 lux 1010 lux

∆T 10 K,

1010 lux 380 lux

∆T

10 K

V

/

V

4

Input Voltage

(

V

in

)

2

0

V

/

V

/

Output Voltage

(

4

V

o

)

2

0

0

10

20

30

40

50

60

70

80

Time/sec

FIGURE 5.31

Performance of an HEH system.

in this section, the closed-loop MPP tracker manipulated the duty cycle of the

boost converter to shift back

V

in

and maintain it always at the MPPT voltage

(

V

mppt

=

6V)ofthe HEH system. By doing so, the total power harvested by

the HEH system increased from 190 to 367

3

.

Wat5V,which was more than

the load power consumption.

To enhance the performance of the wireless sensor node, the solar panel

was exposed to a stronger solar illumination of 1010 lux that can be found

in indoor applications like hospitals and factories. Referring to

Figure 5.31

,

for the time period of 30 to 60 s, there was even more electrical power har-

vested from the HEH system at a solar irradiance of 1010 lux and

T

of 10 K

for powering the indoor wireless sensor node. Referring to

Figures 5.17

and

5.20

with operating conditions of 1010 lux and 10 K, the maximum power

obtained by summing the individual MPPs of the thermal energy harvester

and solar panel was 727

W, and the actual harvested power measured from

the two paralleled energy sources was 690

W. The power difference between

the calculated and measured powers, due to impedance mismatch between

two paralleled energy sources, was 35

W. Taking into consideration both the

power difference and the power losses in the voltage-regulating and MPPT

converters, the net harvested power output to the load through the boost con-

verter with efficiency of 90% was 621

W. This verified the harvested power

boost converter connected to the load resistance of 68 k

was around 6.5 V,

and its harvested power was calculated to be 621

W.

Search WWH ::

Custom Search