Environmental Engineering Reference

In-Depth Information

are verified with the measured P-V curves as seen in

Figure 5.17

for varying

solar irradiance conditions, performed by a characterization setup based on

a fluorescent light source.

Figure 5.17

shows that all of the power curves peak

near the solar panel output voltage of 3.6 V. Conversely, for the power curve

(P-R) plotted in

Figure 5.18

, it can be observed that the MPPs of the solar

panel vary between 27 and 68 k

.Assuch, by setting the output voltage of

the solar panel fixed at 3.6 V, maximum output power can be harvested from

the solar panel under different solar irradiance. Within the indoor lighting

conditions of 380 to 1010 lux, the maximum electrical power that the solar

panel can harvest ranges from 180 to 480

W, respectively.

5.3.3

Thermal Energy Harvesting Subsystem

In the TEH subsystem, a miniaturized thermoelectric generator (TEG) housed

in the thermal energy harvester is used for converting thermal energy into

electrical energy. The thermal energy, generated from the heat source at a cer-

tain high temperature of

T

H

,ischannelled through the enclosed TEG via a thin

film of thermally and electrically conductive silver grease between them to

the heat sink. The residual heat accumulated in the heat sink is then released

to the surrounding ambient air at a lower temperature

T

C

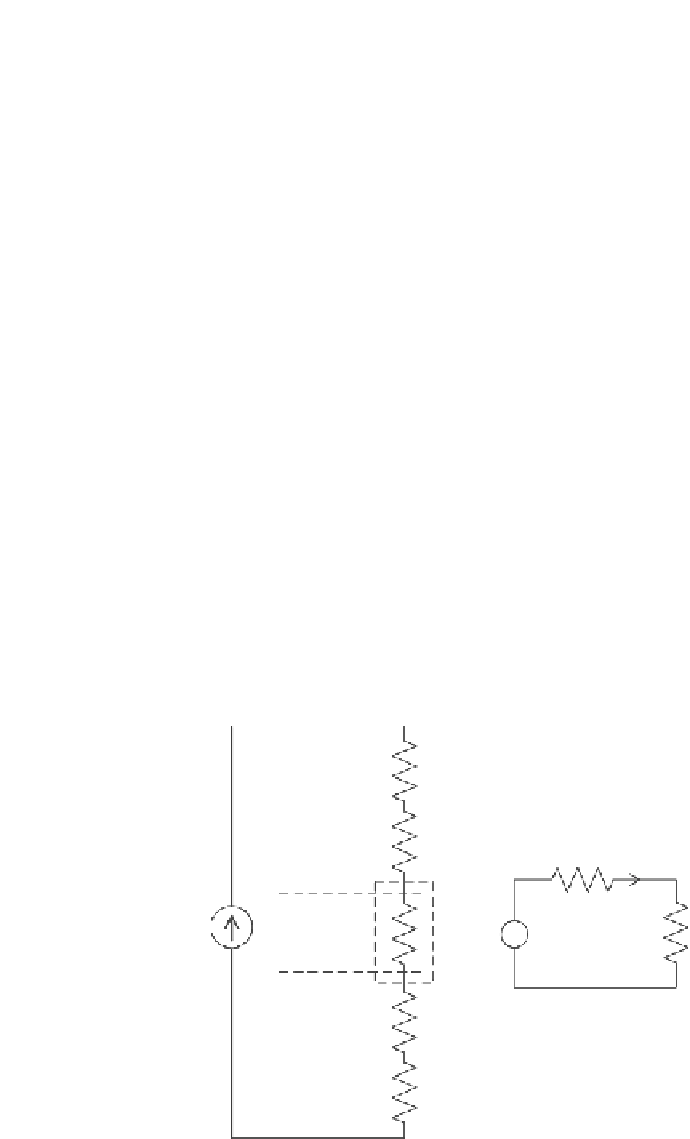

.Anequivalent ther-

mal circuit model of the thermal energy harvester that illustrates its thermal

and electrical characteristics is provided in

Figure 5.19

.

As observed in

Figure 5.19

, the temperature difference

T

TEG

across the

junctions of the TEG is lower than the temperature gradient,

T

C

,

that is externally imposed across the thermal energy harvester. This is because

T

=

T

H

−

T

H

R

con

(

H

)

R

g

(

H

)

R

s,TEG

i

TEG

Hot Side,

T

HJ

P

+

TEG

∆

=

P

*

R

TEG

T

TEG

V

oc

=

S

*∆

T

TEG

R

TEG

+

-

V

TEG

R

L

-

Cold Side,

T

CJ

R

g

(C)

R

con

(C)

T

c

FIGURE 5.19

Equivalent electrical circuit of the thermal energy harvester.

Search WWH ::

Custom Search