Environmental Engineering Reference

In-Depth Information

TABLE 4.1

Technical Specifications of TH7R

TH7R Dimensions and Physical Properties

Weight

g

18

Dimensions

mm

95.3

×

73.4

×

0.53

PZT thickness

mm

0.25

Static capacitance

nF

166

Maximum voltage

V

300

Vertical displacement

mm

9.55

it on a shoe. Danak et al. [120] also researched ways to optimize the design of

an initially curved PZT unimorph power harvester. A mathematical model

was created that predicts the power output of the device. From this model,

relationships between generated charge and initial dome height, substrate

thickness, PZT thickness, and substrate stiffness were established.

THUNDER transducers are commercially available in a variety of sizes and

force displacement characteristics, each with very different electromechani-

cal characteristics. According to Danak et al. [120], the power available from

a flat piezoelectric transducer under 31-mode bending excitation is gener-

ally proportional to the volume of the material and the vertical displacement

induced. Therefore, while constrained by the size, comfort, and vertical dis-

placement experienced by the human pressing, the volume of PZT piezo-

ceramic is maximized when selecting the appropriate transducer. Hence, the

TH7R piezoelectric device is chosen, and its technical specifications are shown

in

Table 4.1

.

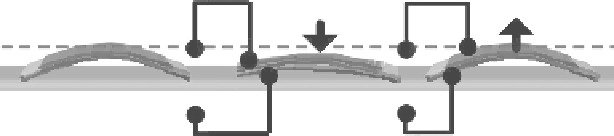

4.2.2

Characteristics and Performance of THUNDER

Lead-Zirconate-Titanate Unimorph

The unique prestressed characteristic and convex shape of the THUNDER

piezoelectric material is used as a natural “press-and-release” mechanical

switch. The natural “press-and-release” process of the piezoelectric material

illustrated in

Figure 4.17

consists of displacing the transducer from its equi-

librium position, reaching maximum displacement (stress), before allowing

Zero Voltage

State

Positive Voltage

State

Negative Voltage

State

+

-

-

+

1

2

3

FIGURE 4.17

A depressing cycle of the prestressed piezoelectric diaphragm material.

Search WWH ::

Custom Search