Agriculture Reference

In-Depth Information

not, however, withstand the high internal pressure

developed during processing and must therefore be

sterilised in media (water or steam and air) capable of

providing an external pressure sufficient to balance the

internal one.

For the thermal processing of the open or sanitary

can, flame sterilisation, for example, the Tarax flame

steriliser developed in Australia, combined with rotation

of the can, is now used for certain products. This system

has the advantage of being relatively cheap and is capable

of providing very efficient heat transfer in those prod-

ucts with some liquid.

Future forms of thermal processing may involve the

use of microwave energy, hydrostatic sterilisers using

high-efficiency steam and fluidised-bed systems.

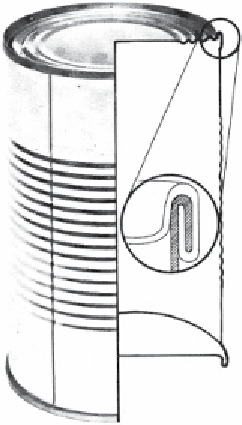

Section

through

seam

Traditional canning methodology

As a food container, the metal can - first developed by

Nicolas Appert in France in 1795 - has certain virtues

possessed by no other type of container for heat-pro-

cessed foods (Fig. 4.2). It has a high conductivity, which

is of importance during processing; it cannot easily be

broken; and being opaque, any possible deleterious

effects of light on the foodstuff are avoided.

There are currently three main methods of can manu-

facture, the most common being the traditional

three-

piece food can

. Constant research and development are in

operation to improve techniques and designs. Over the

years, the amount of metal in cans has been reduced, and

soldering, which involved the use of lead, has long been

discarded. The process of can manufacture begins with

sheets of tinplated steel (Fig. 4.3) (1). Some of these may

be coated with lacquer and dried in ovens for 15-20

minutes. Lacquers are used to prevent contact between

food and tinplate and vary in type according to the class

of food to be canned - acid foods like fruit, high-protein

foods such as meat, etc. The lacquer-coated sheets are

cut into lengths and widths for specific can sizes (2, 3).

Individual strips are then rolled into cylinders (4), and

the two edges of the cylinder drawn together with an

overlap which is

electrically welded

(5). At this stage, the

cylinders are given a further coat of lacquer on the seams

and dried in an oven. A lip is next formed on each end of

the cylinder (6). Separate ends (lids and bases) (7) are

made in a different area, and the rims of these ends are

curled, and a sealing compound is injected into the curl

(8). The base is next joined to the cylinder body, the seal-

ing compound forming an airtight seal. The cans, with

their separate lids, are now ready for use by the food

processor.

The

two-piece drawn and wall-ironed can

(DWI) con-

sists of two pieces of tinplate, the body and base being

formed from one piece of metal and the lid from another.

Figure 4.2

Modern food can showing section through seam

(by courtesy of Metal Box Ltd).

The body and base are shaped from a thick piece of tin-

plate which is drawn up, ironed and ridged for strength

and then given a coat of lacquer.

The

drawn and redrawn

(DRD) can is manufactured

from two pieces of tinplate, the body being made from a

disc-shaped piece, lacquered on both sides and drawn up

to form a shallow cup and then redrawn a second and

third time to make a deep cup.

Although the term

tin can

is applied to currently used

containers, this is something of a misnomer as they are

constructed of mild steel with a thin coating of pure tin

representing about 1.5% of the can's weight. Coating of

the steel plate is necessary to prevent corrosion, and in

some foodstuffs, such as fish or fruit, a fish or fruit

lacquer is used. Unsightly staining of the surface of

certain foodstuff, known as

sulphiding

, may also occur

and is avoided by use of a phenolic meat lacquer or a

sulphur-resistant lacquer. An alternative method of

avoiding sulphiding is now being extensively employed

for meat packs and consists of chemical treatment of the

inside of the can to form an invisible film, the solution

used being a strong alkali bath containing phosphates

and chromates.

Treatment of food to be canned

The food to be canned must be clean and of good qual-

ity; the use of any material showing obvious signs of

spoilage will result in deterioration in quality of the

product. Many foods, particularly fruits and vegetables,

are scalded or blanched before treatment, to cleanse the

product, to produce shrinkage which permits adequate