Agriculture Reference

In-Depth Information

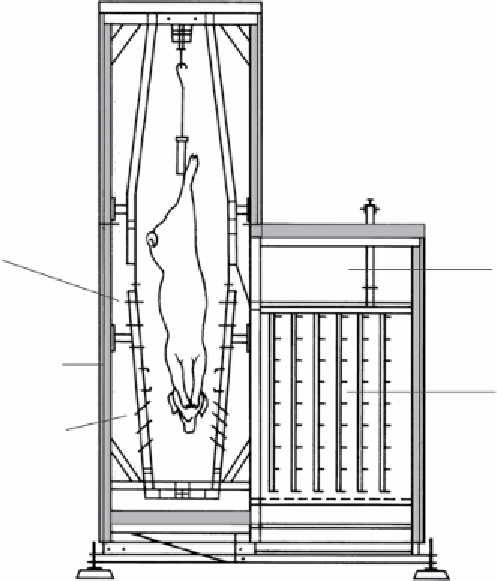

Distribution

nozzles

Channel for recirculated air

80 mm stainless steel

insulating elements

Humidifying zone

Circulation chamber

Figure 3.7

Vertical scalding of pigs showing, cross section of humidifying chamber, channel for recirculated air and humidifying zone

(by courtesy of SFK AmbA, Copenhagen, Denmark).

also be given to the capacity of each chamber to permit

optimal energy use and the implementation of an effec-

tive cleaning schedule.

In addition, offal on trays and A-frames can be chilled

in the same chill as the carcases. However, boxed meat

may not be stored in the same chill as exposed meat, so if

the intention is to package and store the offal prior to

dispatch, a separate chill will be required.

The carcases must be hung in such a way as to allow

free movement of cold air around them; rail spacing

should be 0.9 m for beef, 0.7 m for pigs and 0.5 m for

lambs. Theoretically, the minimum space between car-

cases on rails should be 0.3-0.4 m. However, pig carcases

in particular may be packed much tighter in the chill,

often touching, without significant 'hot spots' being sub-

sequently detected.

The positioning of the chiller unit within each chill

room is important to ensure efficient operation and

hygienic operation. Poor positioning of the unit with, for

example, the steel beams supporting the rail system

interfering with airflow or drip water or condensate fall-

ing onto carcases, particularly during defrosting cycles,

should be avoided. The effectiveness of the unit's system

to remove condensate from the evaporator via a drip tray

and pipes is important and usually requires these to be

well insulated and may incorporate a heater.

It is essential to record temperatures in order to con-

trol the chilling process, preferably on a continuous basis

using charts or computer-generated records. The record-

ing of relative humidity is also of value as is the occa-

sional checking of air speed.

Internal finishes of chills should be durable and

impervious, with good insulation and floor drainage.

Areas of walls where contact with carcases may occur,

for example, on loading, should be protected with stain-

less steel or plastic sheeting.

It is vital that chill and freezer doors be close fitting

and that they be provided with an internal opening

device to avoid personnel being closed in the rooms.

Detained meat room

Carcases detained for further examination should be

routed by a special rail to the

detained meat room

, which

should be located adjacent to the main slaughterhall

inspection points in order to achieve close liaison over

disease findings. All parts of the carcase must be

identifiable pending the final decisions. From this

detained meat room, the overhead rail must reconnect

with the main slaughter line for direction of carcases

either to the chill rooms or to the condemned meat

room. It is important that there should be ample space

for the examination of carcases which, being hot at this