Agriculture Reference

In-Depth Information

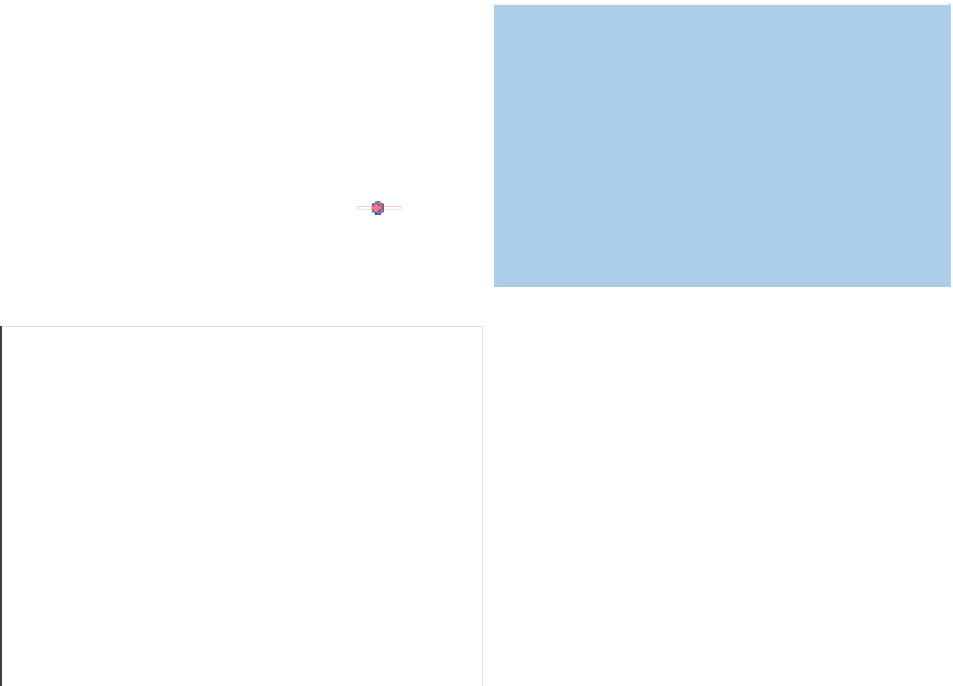

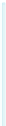

CIP-cleaning and CIP-interfaces 1

CIP-cleaning and CIP-interfaces 2

?

Start pre-rinse

Pre-rinse

Remove rinse

water

Interface

separation

Start

circulation

of cleaning

solution

End pre-rinse

Start cleaning

Cleaning

CIP-cleaning and CIP-interfaces 3

CIP-cle

aning and CIP-interfaces 4

Start disinfection or second cleaning

step....

Continue through all steps as

described

Use final rinse water to fill up pre-rinse

tank

End cleaning

start rinse

again

Push

detergent

back to tank

?

Interface

separation

Rinse

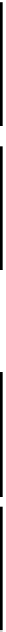

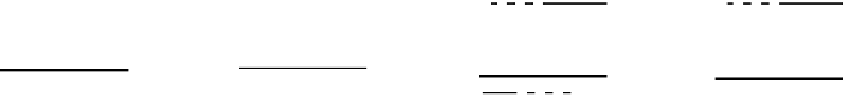

Figure 5.11

Shows a graphic representation of a complete CIP sequence (Reproduced with permission from Ecolab. © Ecolab).

temperature of a steam hose had a disinfecting effect,

this is in fact not the case, as expansion at the nozzle

causes rapid cooling even at short distances, while

conduction of heat away from the point of impact by the

surface (usually a metal) means that sufficiently high

biocidal temperatures on the surface itself are never

reached. Live steam can also carry corrosion products

from pipelines or carry-over of boiler treatment chemi-

cals, neither of which is desirable hygienically.

Similarly,

low-pressure

(around mains pressure or

<10 bar) water systems are inadequate for rinsing meat

or poultry plants, because the water jet lacks sufficient

energy to assist in the cleaning process.

At the other extreme,

high-pressure

rinse systems,

based on either mobile pressure washers or built-in

pump systems, have been widely used. Their use has

been in decline for a number of safety, maintenance and

hygiene reasons. These systems typically function at

60-120 bar, using piston- or plunger-type pumps. They

create a vibration in plumbed-in systems, which can

affect the life of the pipe work, which is narrow bore and

may be reused depending on the amount of dirt they

pick up on each cleaning cycle and on the suspension

and chelating power of the detergent. If too heavily

loaded, detergent solutions may re-deposit old soil or

scale in slower-moving parts of the system. Filtration or

centrifugation can sometimes be used to extend the life

of the solution (Fig. 5.11).

Rinse systems

Meat plants need effective rinse systems for washing

down the plant before and after the foam application and

in some cases for generating the foam itself and applying

disinfectant. A number of different systems are possible.

The rule governing them all is that the cleaning impact

of a water jet on a surface is proportional both to the

pressure of the liquid at the point of contact and to the

volume of liquid per second in the jet.

Traditional

steam hoses

, which mixed live steam

with cold water, are now out of favour for a number of

reasons, principally cost, safety, humidity and conden-

sation. Although it may be thought that the very high