Agriculture Reference

In-Depth Information

be automatically controlled and dosed by conductivity

probe, with the probe being cleaned regularly and the

concentration checked. Location of the probe is impor-

tant in obtaining representative readings. Machines

should be set up for individual tray type; in this respect,

nozzle positions, angles and spray patterns are crucial to

obtaining a consistent hygiene result. If tray type and

shape change significantly, the machine will need to be

reset in order to maintain the required efficacy.

provides an equivalent food safety result. Turning off the

steam or electrical elements in traditional knife disinfec-

tion baths can contribute significantly to the reduction

of a plant's carbon footprint while also gaining other

benefits for operators and product.

Machine washing

Industrial machine washing is typically done with an

automatic or semi-automatic continuous tray wash or

buggy wash machine with spray nozzles arrayed on

booms in separate chambers of the machine or in sepa-

rate cycles for detergent, rinse and sometimes disinfect-

ant. An alternative machine design uses submersion

tanks or flumes, through which the trays are slowly

pulled. A less effective design is the circular carousel,

which runs the risk of contamination of clean trays by

dirty ones as there is only one entry/exit point. Other

machines, especially for buggies and racks, may wash

each item individually in a batch process. All machine

types represent an expensive capital investment and are

critical to the hygiene of direct food contact surfaces.

Wash machines generally are large consumers of water,

especially if not properly maintained and controlled.

Filters should be cleaned regularly and blocked nozzles

cleared. Prevention of liquid carry-over from one cham-

ber to the next is also important. Tray wash machines can

also be a contamination risk to the rest of the factory as

they can produce large quantities of fine, contaminated

aerosols, which may drift with natural airflows into

critical areas. Chemicals used in these machines must

be low foam or even actively de-foaming and should

Cleaning-in-place (CIP)

CIP is used extensively for the interior cleaning of pipes,

vessels, tankers, heat exchangers, fillers, etc. commonly

found in breweries and dairies for the processing of

liquid products. This approach is used in meat and poul-

try plants where giblets or other materials such as bast-

ing oils may be automatically transferred through pipe

systems. The most recent adoption of CIP in food manu-

facturing is in the convenience foods department where

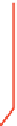

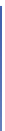

sauces or marinades may be made. CIP involves a pro-

grammed cycle, including timed pre-rinse, cleaning and

rinsing stages, and is nowadays usually automated or

semi-automated with a system of valves, pumps and

detergent tanks, often controlled by microprocessor

(Lorenzen, 2005) (Fig. 5.8).

The main points to consider include the following:

Flow velocity

- It should be sufficient all parts of the

system to cause turbulent flow. This is generally around

1.5-2 m/s. Where pipe diameters vary in the one system,

the largest pipe should have this flow rate. Failure to

comply with this flow rate means smooth 'laminar' flow

Multiple use of cleaning solutions and rinse water

Detergent

Pre-rinse water

Object to be cleaned

Fresh water

Disinfectant

CIP-supply

CIP-return

Figure 5.8

Diagrammatic representation of a standard CIP system (Reproduced with permission from Ecolab. © Ecolab).