Agriculture Reference

In-Depth Information

Central water

pump

Central

chemical stock

and pump

Wall-mounted satellites

to apply central and

local hygiene

chemicals

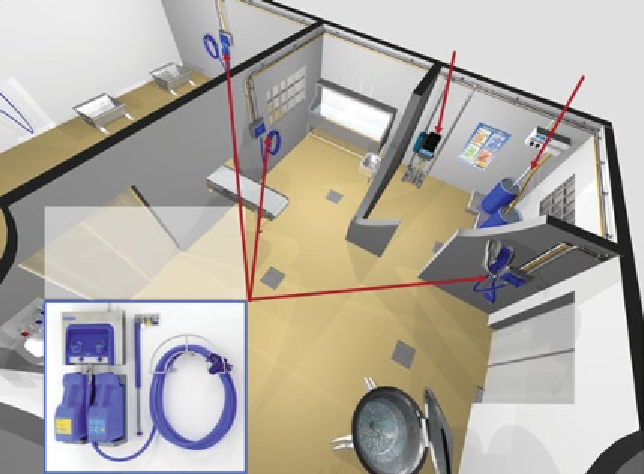

Figure 5.6

Demonstration room showing installations of hybrid central/satellite foam and rinse stations (Reproduced with permission

from Ecolab. © Ecolab).

Spray

Prior to the advent of foam cleaning technology, this

method was widely in use; however, it is now seldom

used for the application of detergents. Spray cleaning

uses a gun and/or lance linked to a pressurised water sys-

tem; hygiene chemical induction is via an injector. This

may be achieved using satellite foam and rinse equip-

ment, mobile equipment or more simply via a backpack

sprayer of diluted product. Using this method for clean-

ing is wasteful, it is difficult to see the application, it is

often repeated unnecessarily, and the hygiene chemical

runs off rapidly from vertical surfaces. It is slower and

inferior in performance to foam cleaning. Conversely, it

is the usual method of application for disinfectants,

though as discussed earlier disinfectants can be applied

as foams. The subtle difference in the case of disinfection

is that this application is routinely concerned with food

contact surfaces, it is a faster application than foaming

and dependent on area and equipment to be treated and

spraying via a satellite injector system or a backpack

sprayer can both provide efficient outcomes.

with aerosols (debris and water droplets). Fogging sys-

tems can be small portable devices or built-in automatic

central systems. Fogging is only worthwhile if the rest

of the hygiene programme is properly carried out.

The important parameters for effective fogging are the

matching of the volume of liquid being fogged to the vol-

ume of the room, the temperature, the relative humidity

and the rate of air change. Ideally, saturation of the air,

with very fine droplets (10-20 µm) which stay suspended

for a long time, gives the best results. Failure to create the

correct fog droplet size and volume can mean that only

the uppermost surfaces of the plant receive the disinfect-

ant as it rains down and the air itself may remain largely

unaffected.

Knife and cutting tool disinfection

during processing

The EU hygiene regulations have over many years

demanded that knives and cutting tools used in animal

slaughter/processing be disinfected in hot water at 82°C

(Council Directives, 64/433/EEC, 92/116/EEC, 95/68/

EEC). It has been known for some years that this method

has some significant drawbacks (SCVPH, 2001); some

are listed below:

•

The cost of producing the hot water

•

The maintenance of steriliser boxes, particularly of

heating elements

•

Low comfort of the operator

•

Creation of considerable volumes of water vapour and

associated condensate

Fogging

Aerial fogging uses compressed air or other equipment

to generate a fine mist of disinfectant solution, which

should hang in the air long enough to fill the room

volume before settling on walls and difficult-to-reach

surfaces. Fogging is primarily focused on complete sur-

face disinfection in a defined enclosed area, though it is

possible to reduce airborne micro-organisms associated