Biology Reference

In-Depth Information

fi sh protein hydrolysates prepared using alcalase had less bitter principles

as compared to those made with plant proteases like papain (Hoyle

and Merritt, 1994; Kristinsson and Rasco, 2000b). Recently hydrolysis

conditions for preparation of protein hydrolysates from freshwater fi sh

processing wastes using alcalase have been optimized (Bhaskar et al.,

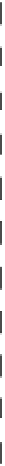

2008). The fl ow-chart for preparation of fi sh protein hydrolysate using

commercial proteases is outlined in Fig. 10.3.

Visceral waste

Homogenize

Heat Treatment (85°C, 20 minutes)

Cool and Centrifuge

Fat layer

Protein rich residue

Extract with Distilled water (1:1 w/v; 3 times)

Centrifuge

Residue

Protein Extract

Hydrolyze with Alcalase (Optimized Conditions)

Heat inactivate the enzyme (85°C; 20 minutes)

Filter/Centrifuge

Spray dry

Fig. 10.3

Flow sheet for the production of protein hydrolysate from the visceral wastes of

Catla (

Catla catla

) using alcalase under optimized conditions

.

(from Bhaskar et al., 2008).

Although, alcalase is favoured by several researchers in the preparation

of fi sh protein hydrolysate (Benjakul and Morrisey, 1997; Kristinsson

and Rasco, 2000b; Bhaskar et al., 2007a, c), it requires a suitable pH for

its activity. However, pH of fi sh visceral wastes usually varies between

5.85 and 6.25 (Bhaskar and Mahendrakar, 2007; Bhaskar et al., 2007a, c).

Adjustment of pH prior and/or during hydrolysis, although is common,

is not industrially desirable as the added acid/alkali results in unwanted

inorganic mass (salt) that may result in undesirable effects and/or may be

diffi cult to remove later in the hydrolysate recovery process (Aspmo et al.,

2005). In this regard, neutral proteases of microbial origin look promising

as natural (

in situ

) pH of the visceral waste itself can be utilized to prepare

protein hydrolysates (Guerard et al., 2002; Dauksas et al., 2005; Nilsang et

al., 2005; Dumay et al., 2006; Bhaskar and Mahendrakar, 2008).