Environmental Engineering Reference

In-Depth Information

of automobile catalytic converters, leading to increased tailpipe emissions of both nitrogen

oxides (NOx) and CO

2

.

Governments worldwide have responded by enacting laws to restrict the quantity of

sulfur allowed in fossil fuels, primarily those intended for transportation. In the past 10 years,

allowable levels of sulfur in transportation fuels have diminished from 2,000-5,000 parts per

million (ppm) to less than 500 ppm; recent regulations proposed by the Directive of the

European Parliament [4] and the EPA [5] will lower these levels to below 350 ppm. By 2010,

even lower restrictions (less than 10-15 ppm in practice) are expected [1].

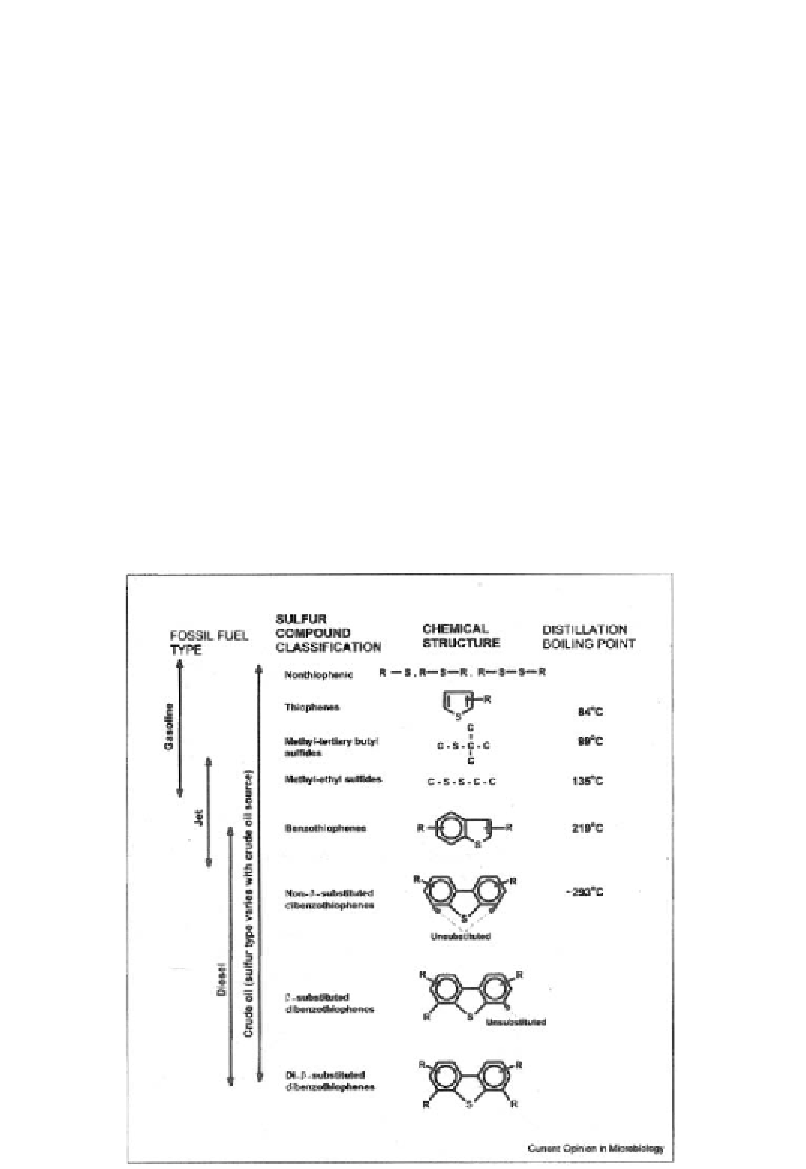

1.1. Hydrodesulfurization

The primary conventional technology used to remove sulfur from crude oil is

hydrodesulfurization, or HDS. By subjecting crude oil to elevated temperatures and hydrogen

partial pressure in the presence of a CoMo/Al

2

O

3

or NiMo/Al

2

O

3

catalyst, reactive sulfur

components such as mercaptans, sulfides, and disulfides are converted to H

2

S and

hydrocarbons. Lower boiling point fractions of crude oil contain primarily these aliphatic

organosulfur compounds and are therefore desulfurized with great success by HDS. In higher

boiling point fractions, however, the organosulfur compounds primarily contain thiophenic

rings, including thiophenes, benzothiophenes, and their alkylated derivatives. Unfortunately,

HDS is much less efficient in the desulfurization of these compounds (Figure 20), with the

result that so-called deep desulfurization technologies are being actively explored [7].

Figure 20. Organosulfur compounds present in fossil fuels [7].