Environmental Engineering Reference

In-Depth Information

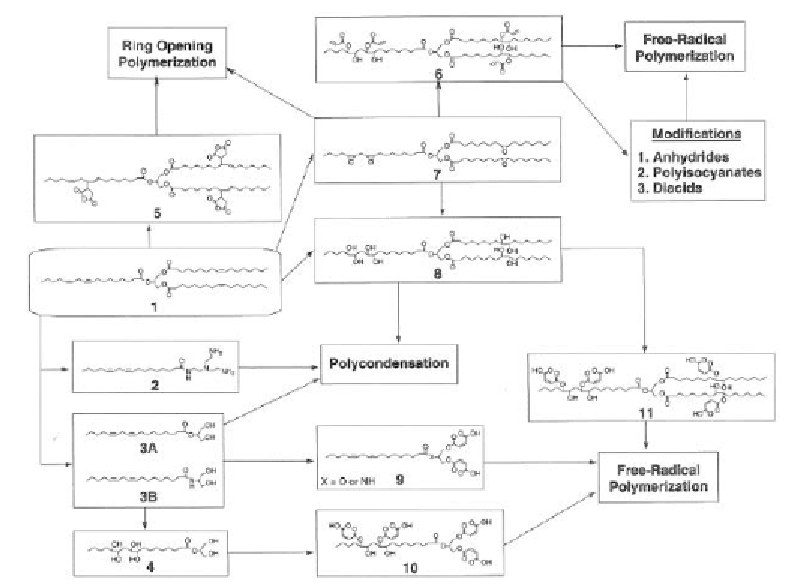

Figure 13. Pathways for the chemical conversion of plant triglycerides (1) into different classes of

chemically reactive species useful for making plastics (from Wool [14]).

A variety of chemistries is available for turning such oils into useful polymeric products

and these are discussed at length in the recent compilation by Wool from which Figure 13 is

taken [14]. The various functionalities available include amines (structure 2), monoglycerides

(3A, 3B), polyols [4], maleates [5], acrylates [6], epoxy [7], hydroxyl (8), and maleate half

esters [9, 10, 11]. Such monomers are easily incorporated into well established vinyl ester

resin formulations and can serve to decrease volatile organic compound (VOC) emissions in

styrene containing formulations. Other polymeric materials that can contain significant plant-

oil content include polyurethanes

2.4. Cellulose, Lignin, and Reinforced Composites

As is evident from the preceding sections, many plastics can be improved substantially

for materials applications by the introduction of reinforcing constituents to form composites.

Indeed, certain biosubstances such as proteins can only form usable materials as components

of composites. In the interest of minimizing environmental impact, natural cellulose-based

fiber reinforcements have become especially attractive.

2.4.1. Cellulose.

Cellulose, the most abundant biological substance on Earth, is a polymer

of glucose with both amorphous and crystalline regions in its native state (see Chapter IV.

Bioethanol for additional structural details). Although cellulose is most widely applied as a

reinforcing agent in composites, it can also be used directly or as an esterified derivative in

place of petroleum as a feedstock to make cellulosic plastics, particularly as flexible films.

The most widely used cellulose esters are cellulose acetate (CA), cellulose acetate propionate