Graphics Reference

In-Depth Information

Because most pressruns use paper slightly larger than the finished piece or gang several

pieces on a single sheet, waste must be cut away and pieces cut apart. All straight line

cuts are called

trims

. Trim lines are indicated by crop marks so that whoever is trimming

the job will know where pieces needed to be cut. Trimming a job is included in the cost

of printing, and is not the same as perforating, making die-cuts, drilling, or punching

holes. These applications are performed at an additional charge. For more information

on perforating, die-cuts, drilling and punching, see Finishing Techniques.

Finishing techniques are applied after a job is printed to create a special effect that can't

be achieved with ink. They also include special cuts and trims that are part of the design

or applications that make a piece easy to fold, tear, or ready for binding.

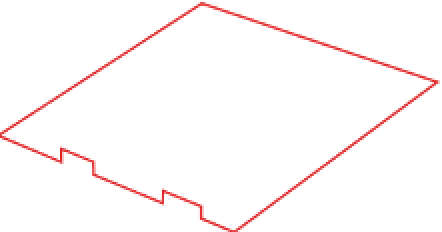

Embossing:

Paper is pressed between

two molds called

dies

, typically made

from magnesium or brass. The molding

of the paper between the dies results in

a raised impression. If an impression

is molded so that it is lower than the

paper's surface, it is called a

deboss

.

Embossing can be combined with a

printed image or foil stamping to enhance

the three-dimensional appearance of the

image. An embossed impression made

independent of a printed or foil-stamped

image is called a

blind emboss

. Soft,

uncoated papers generally take a bet-

ter embossed impression than hard or

smooth coated papers. Papers with a tex-

tured finish are often preferred because

they render a smooth impression that

contrasts favorably with the surrounding

texture. Text and light to midweight cover

stocks work best. Lightweight bonds

and writing papers tend to be too thin to

show off an emboss, whereas, heavier

cover weight stocks can be too thick to

be molded. Embossing is frequently used

on brochure covers, stationery, business

cards, and pocket folders.

Embossing requires two matched dies (male and female

counterparts). One of the dies is heated as the paper is

pressed between, resulting in a raised impression.

Search WWH ::

Custom Search