Agriculture Reference

In-Depth Information

Undoubtedly only the very best of craftsmen could be tasked with setting out,

hewing and then building ornamental cut-moulded brick chimneys. Full-size

plans and elevations of the appropriate parts of the bases, shafts and heads

of the stacks would be drawn from which templets were obtained (Fig. 16).

Plans provided individual templets for the many types of brick shapes as well

as course templates, or moulds, to suit particular overall plan shapes, whereas

elevational drawings provided templets for the profiled shapes of most vertical

cut-mouldings. Shafts could be polygonal with canted bricks, some had contin-

uous patterning with simple geometrical shapes like a square or more ornate

with diamonds or hexagon detailing.

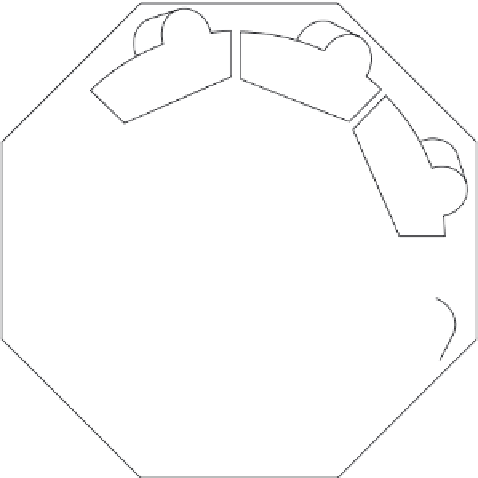

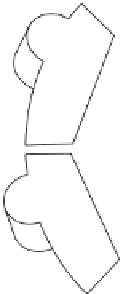

Where there was a vertical spiralling profile on the shaft, like the rope, or

cable, moulding, as seen in the Bridewell brick above, the establishment of

the templets was then altered to accommodate the change in profile through

the height, or gauge, of a particular brick (Figs 17 and 18). On elevation the

spiralling would be viewed as a regular stepping-off of measurements around

the circumference of the shaft. Obtaining those templets was achieved from

a plan view that established the offsets of both the lower and top beds of the

individual brick. Working to a centre line, these two templets - sometimes fit-

ted with corners to secure them to the brick as 'clip' moulds - would then be

held to the bed and to the top of the brick, at the correct vertical distance

apart, or gauge, and scribed. The brick could then be cut precisely by work-

ing between the two fixed points of reference and thus to the desired shape

(Fig. 19).

Figure 17

The positions of the

two templets A and B,

have been imposed by

the author onto the

plan to emphasise how

they were obtained.

(Drawing reproduced

by kind permission

of Robert Lamb, W

T Lambs, Bricks and

Arches Ltd)

A

B