Biology Reference

In-Depth Information

there may be some possibility for a special kind of microcomponents

with small contacts, which have the characteristic of larger surface-

to-volume ratios, as the corrosion process likely depends on the

exposed surface area.

12.3.3

Microscale 3D Self-Assembly

Compared to conventional 2D microscale self-assembly, 3D self-

assembly processes are more challenging, as they set higher

requirements for both the components, the substrate and the self-

assembly mechanisms.

In microdomains, capillary force dominates over gravity, and

has been exploited to construct 3D self-assembled structures. Our

group has demonstrated some work of achieving 3D microscale

self-assembly by applying capillary force provided by hydrophobic

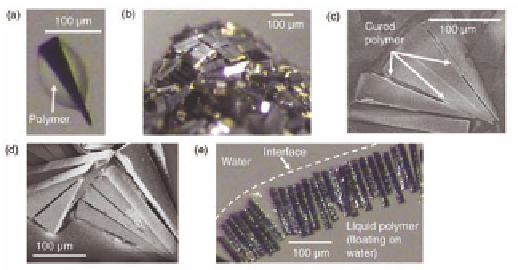

and hydrophilic interactions [12]. As shown in Fig. 12.17, a cross-

linkable liquid polymer was used as an intermediate to promote the

binding of microscale silicon parts into 3D structures. In the review,

we also systematically quantified the effect of various parameters

that affect the polymer-deposition process, such as the surface

energy of template regions, polymer concentration, and size of the

template regions.

Figure 12.17

Self-assembly of triangular, microfabricated silicon parts.

(a) One unassembled part. (b) Large collection of microscale

components due to deposited polymer. (c) Self-assembly of

a small number of parts into the desired configuration. (d)

Self-assembly from a different experiment. (e) Collection of

stacked triangular parts floating near the edge of a polymer

droplet on a water surface. Reprinted with permission from

Ref. [12]. Copyright 2006 IEEE.

Search WWH ::

Custom Search