Biology Reference

In-Depth Information

The ability to use a plastic substrate stems from the fact that

the required temperature for this one-step self-assembly process

is lower than 100

C, which is due to the very low melting alloys.

For 2D microscale self-assembly applying low melting point alloys,

two key issues must be considered. One is the limited size scale of

microcomponents, and the other one is the selection of alloys and

fluidic media. In the above two reports, we have assembled FETs

ranging from 100 to 300

°

m in diameter. The

low melting point alloy we used was 44.7% Bi/22.6% Pb/19.1%

In/8.3% Sn/5.3% Cd, which has a melting point of 47

µ

m, and

µ

-LEDs of 320

µ

°

C.

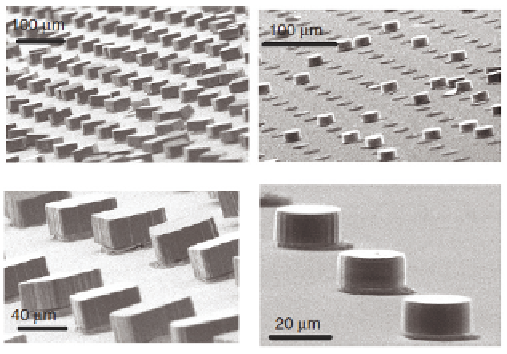

In an effort to fully characterize these two key issues, our group

has reported a systematic study to answer how small molten alloy

contacts can be made and which alloy composition performs best

[11]. In this review, we investigated six alloys with melting points

above 160

°

C and nine fluid environments with boiling points below

160

C. The results showed that the only successful combination

was an eutectic Sn

°

−

Bi alloy and glycerol. Using this combination, we

presented a rapid self-assembly for microcomponents of 40

µ

m (a

µ

yield of 84%) and 100

m (a yield of 95%). For a smaller scale, such

µ

as 20

m, the yield decreased to 15%. The results for the assembly

of 40 and 20

µ

m components are shown in Fig. 12.15.

Figure 12.15

SEM images of self-assembly with 40 and 20

m parts.

Reprinted with permission from Ref. [11]. Copyright 2008

IOP Publishing Ltd.

µ

Search WWH ::

Custom Search