Biology Reference

In-Depth Information

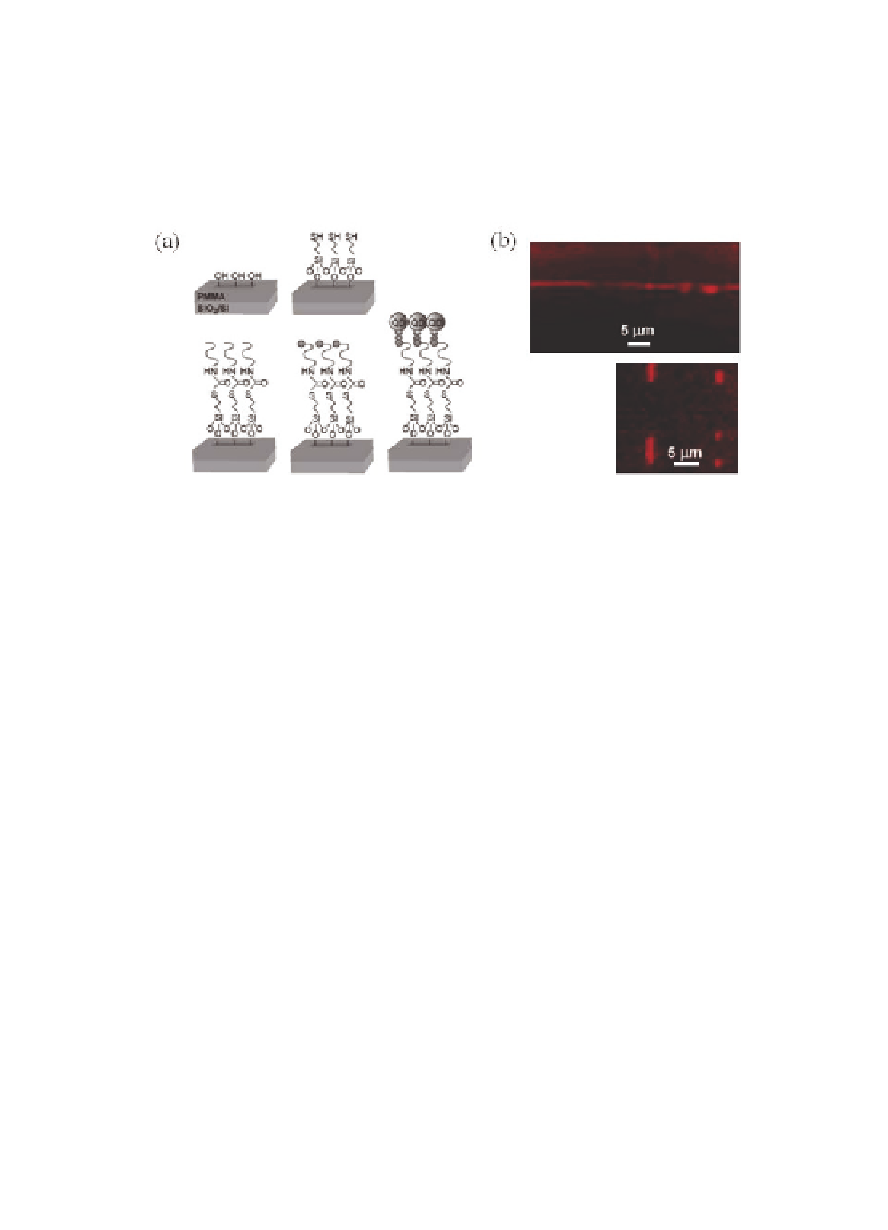

Fabrication of nanophotonic QDWs was achieved using both a

DNA-mediated self-assembly approach and a two-layer molecular

self-assembly procedure based on specific covalent bonds [5,6].

For the DNA process, as depicted in Fig. 12.8, straight and cornered

trenches were patterned on the surface of polymethylmethacrylate

(PMMA) on Si\SiO

using electron-beam lithography.

2

Figure 12.8

QDWs based on DNA-mediated self-assembly of QDs. (a)

Schematic of the self-assembly chemistry. (b) Fluorescence

micrographs confirm QD immobilization as 5

×

1

µ

m

2

, 2

×

m

2

, and 1

m

2

patterns (left), and 1

1

m wide QDWs

(right). Reprinted with permission from Ref. [6]. Copyright

2006 American Chemical Society.

µ

×

1

µ

µ

The trenches define the overall shape of the waveguides. The

Si substrate was chosen to promote integration with existing

circuit technologies. Hydroxyl groups on the SiO

surface act

as anchors for the first assembly step, i.e., the deposition of

3-mercaptopropyltrimethoxysilane (MPTMS) molecules. X-ray

photoelectron spectroscopy (XPS) on the exposed and control

samples confirmed the presence of self-assembled molecular layers

of MPTMS. Acrylamide-modified single-stranded DNA (ss-DNA)

binds specifically to the thiol (SH) termini of the MPTMS molecules

at the bottom of the trenches, thus creating highly specific binding

locations to the exact complementary DNA chain. The binding

specificity of the two complementary DNA strands is utilized to allow

the deposition of QDs in a programmable manner. This is done by

first introducing custom-synthesized biotinylated complementary

DNA (cDNA), followed by streptavidin-conjugated QDs. Finally,

PMMA was removed using a dichloromethane rinse. The QD pattern

remains on the substrate by linking chemistries. DNA assembly

2

Search WWH ::

Custom Search