Biomedical Engineering Reference

In-Depth Information

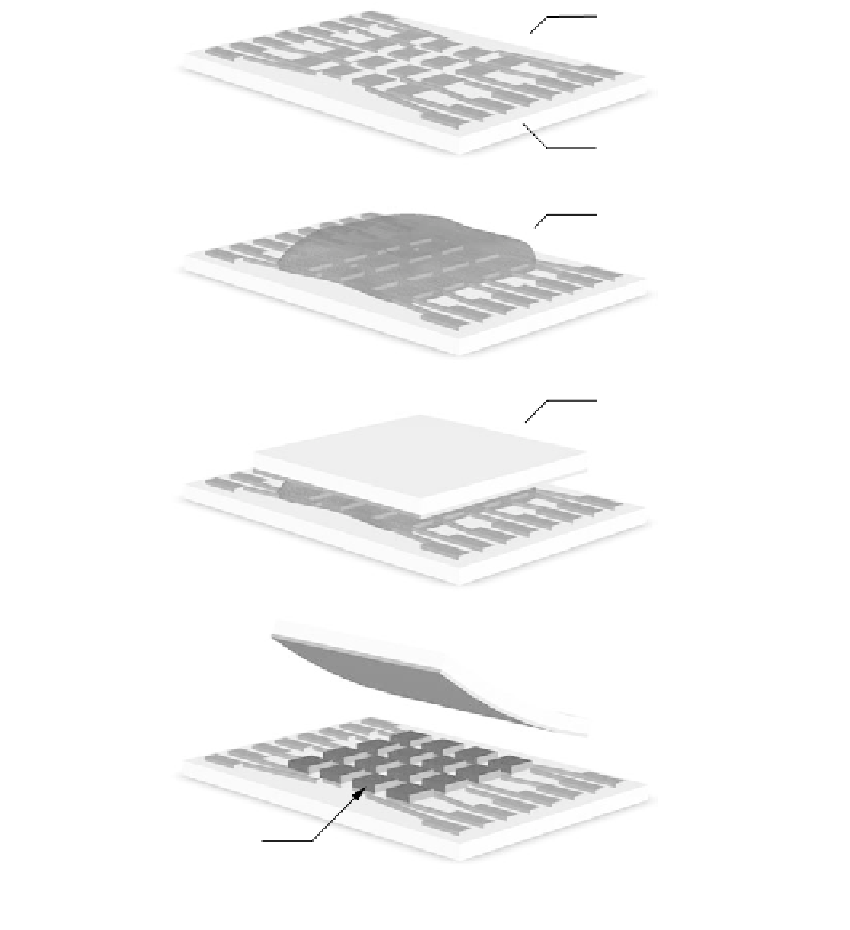

PET substrate

Patterned ITO

(a)

PM suspension

(b)

PET substrate

with continuous

ITO layer

+

(c)

Dried bR film

(d)

FIGURE 17.3

Fabrication process: (a) Patterned electrode surface is cleaned of all residues, (b) 100

L of PM suspension is

spread evenly over the patterned surface, (c) A 1.0-mm plastic spacer (not shown) is placed around the array to

separate the two electrodes, where the bottom ITO electrode is patterned and the top ITO electrode is continu-

ous, and they are connected to the positive and negative terminals of the power supply, respectively. An electric

field of 40 V/cm is then applied. (d) After drying, the top electrode is attached and sealed carefully along the

edge by using fast-curing epoxy resin.

bR-ITO-PET film spectrum (Figure 17.5c). A broad peak, from 550 to 580 nm, was observed

for the dried bR film. Successful deposition shows that the 570-nm absorption peak found

in the PM suspension is also preserved in the dried film. The peak is broader than the PM

suspension due to influences of dehydration on the Schiff base of bR retinal chromophore.

The dried film exhibits an optical density of approximately 0.5 due to high bR concentra-

tion in the film sample, which is greater than the bulk value of 0.3.