Biomedical Engineering Reference

In-Depth Information

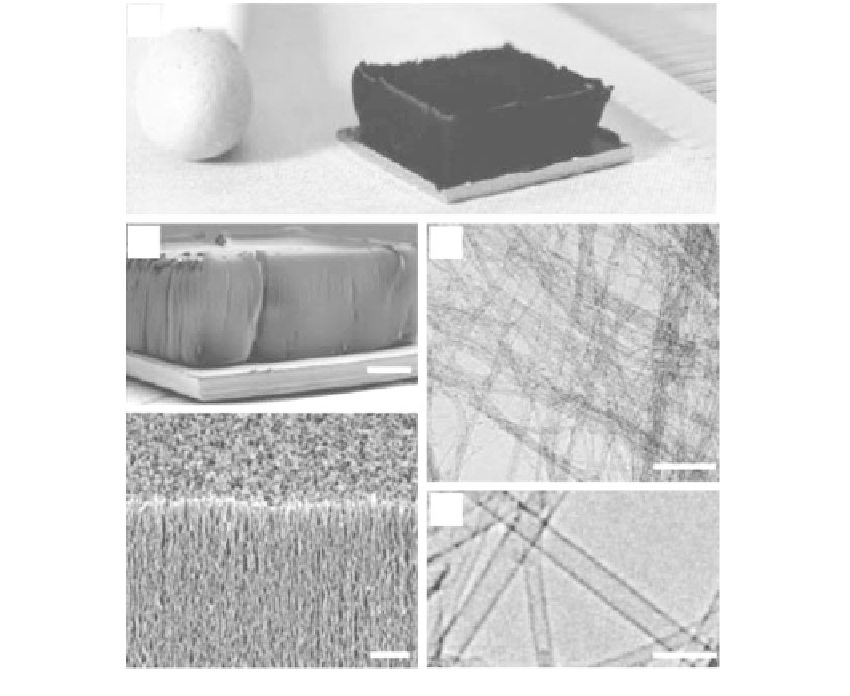

(A)

(B)

(D)

1 mm

(C)

(E)

FIGURE 12.4

SWNT forest grown with water-assisted CVD. (A) Picture of a 2.5-mm-tall SWNT forest on a 7 by 7 mm silicon

wafer. A matchstick on the left and ruler with millimeter markings on the right is for size reference. (B) Scanning

electron microscopy (SEM) image of the same SWNT forest. Scale bar, 1 mm. (C) SEM image of the SWNT forest

edge. Scale bar, 1 mm. (D) Low-resolution TEM image of the nanotubes. Scale bar, 100 nm. (E) High-resolution

TEM image of the SWNTs. Scale bar, 5 nm. (From Hata, K., Futaba, D. N., Mizuno, K., Namai, T., Yumura, M.,

Iijima, S. (2005). Water-Assisted Highly Efficient Synthesis of Impurity-Free Single-Walled Carbon Nanotubes.

Science

, 306, 1362-1364. )

interaction between the metal catalyst and the substrate. In the following two sections,

we will discuss the growth mechanisms and control of the structure of SWCNTs and

MWCNTs, respectively.

12.2.3.1 Single-Walled Carbon Nanotubes

Owing to the direct correlation between the properties of the catalyst particle and the

growth mechanism of nanotubes in the CVD method, synthesis using a controllable cata-

lyst on a predictable substrate is the key to controlling nanotube growth chemistry, mech-

anism, and structure. The understanding of how a catalytic particle initiates growth of

individual SWCNTs is a significant step to controlling their structure and properties. Dai

[30] have investigated isolated iron NPs for the synthesis of SWCNTs by CVD. Their TEM

images revealed the growth process of SWCTs from isolated NPs (Figure 12.5). These

results clearly showed that the diameters of SWCNTs are determined from the diameter of

catalytic particles. The catalytic particles were found to remain on the substrate; this is a

case of the base-growth model. Further, the initial growth of a SWCNT from one catalytic