Biomedical Engineering Reference

In-Depth Information

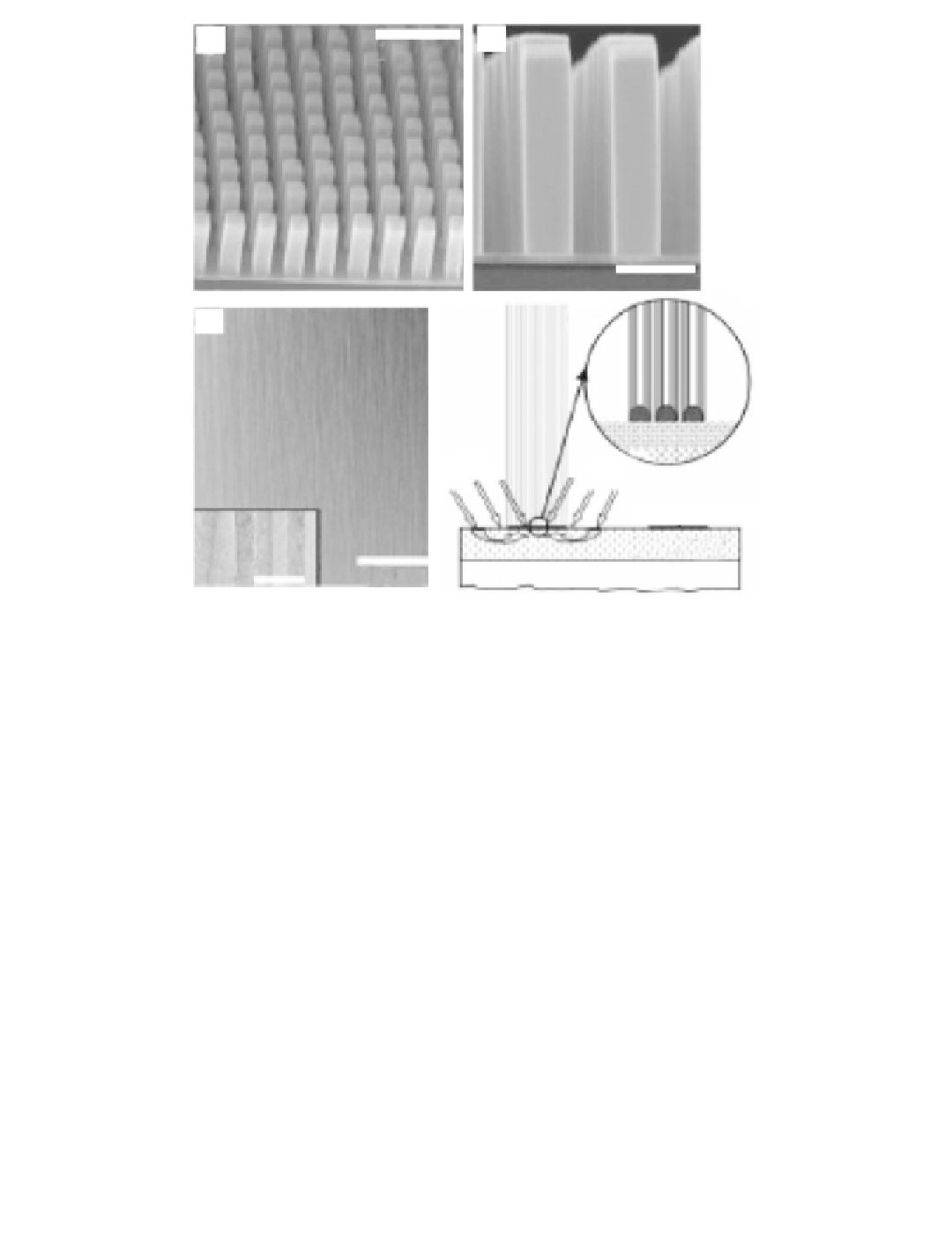

(a)

(b)

150

µ

m

50

µ

m

(c)

(d)

C

2

H

4

C

2

H

4

Iron pattern

Porous Si

Si

75.

µ

m

15

µ

m

FIGURE 12.3

Self-oriented MWCNTs arrays grown by CVD on a catalytically patterned porous silicon substrate. (a) SEM

image of tower structures consisted of aligned nanotubes. (b) SEM image of the side view of the tower. (c) A

high-magnification SEM image showing aligned nanotubes in a tower. Inset: TEM image showing two

MWCNTs. (d) Schematic diagram of the growth process. (From Fan, S., Chapline, M., Franklin, N., Tombler, T.,

Cassell, A., Dai, H. (1999). Self-Oriented Regular Arrays of Carbon Nanotubes and Their Field Emission

Properties.

Science

, 283, 512-514.)

the SWCNTs/catalyst weight ratio reaches 50,000%. They found that the activity and the

lifetime of the catalyst could be enhanced by water. This approach represents a significant

advance toward the realization of large-scale and highly pure SWNT material.

12.2.3

Growth Mechanisms and Structure Control

The unique mechanical and electrical properties of CNTs are directly associated with their

structure, including their diameter, number of shells, and helicity. A thorough understand-

ing of the formation mechanisms for these nanotubular carbon systems is critical to design

procedures for controlling the growth conditions to obtain more practical structures, which

might be directly available for nanotechnology including biosensors.

It has been generally accepted that the growth mechanisms of both SWCNTs and

MWCNTs in the CVD process can be divided into two distinct classes: base-growth and

tip-growth [18]. In the base-growth mode, the catalyst particle remains on the support

surface and the nanotube elongates while maintaining a closed-end. In the tip-growth

mode, the catalyst particle is lifted off the support surface by the growing nanotube and

carried along at the tube end. The operation of these two modes depends on the