Biomedical Engineering Reference

In-Depth Information

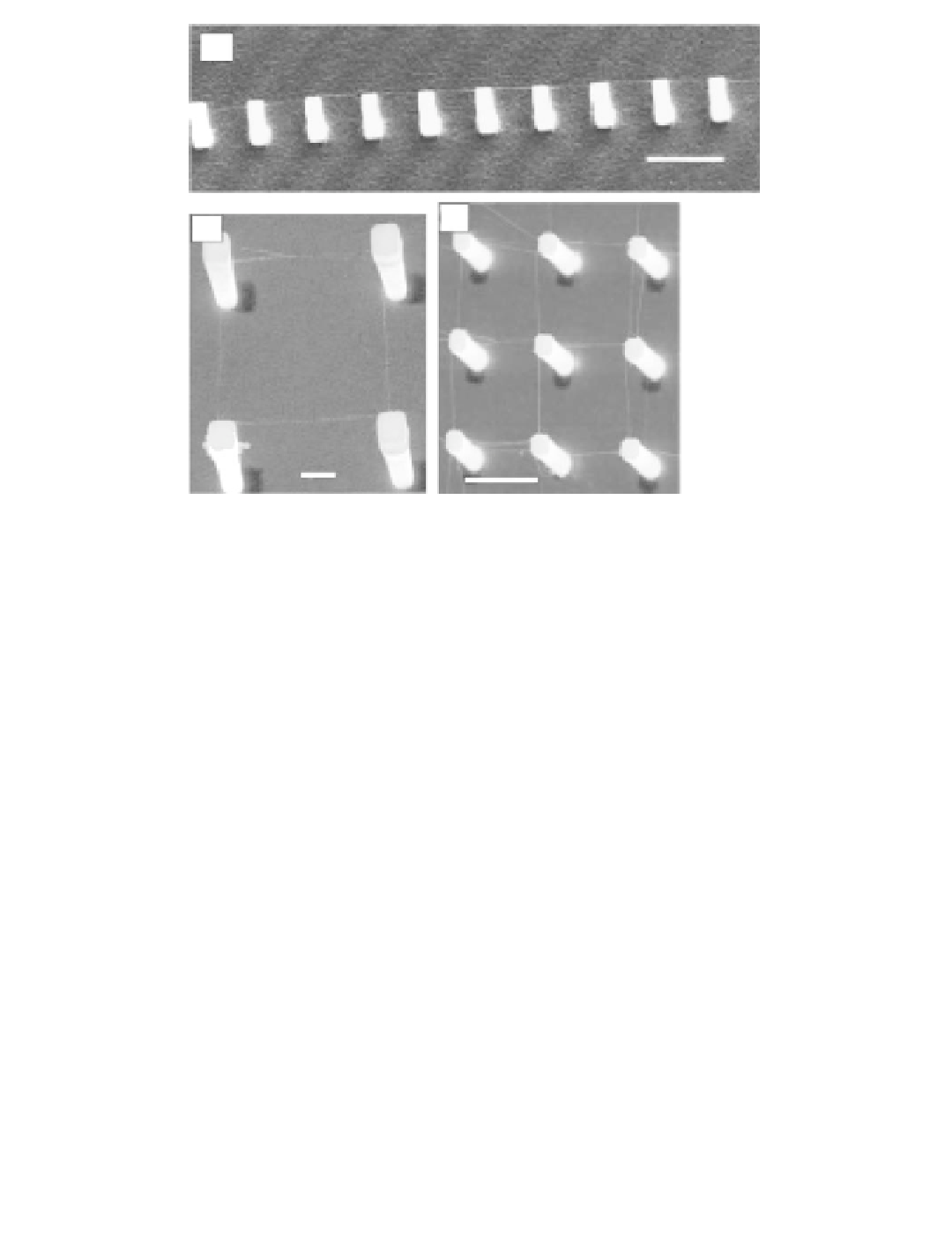

(a)

10

µ

m

(c)

(b)

1

µ

m

0.5

µ

m

FIGURE 12.2

Directed growth of suspended SWCNT. (a) A nanotube power-line structure. (b) A square of nanotubes. (c) An

extensive network of suspended SWCNTs. (From Franklin, N., Dai, H. (2000). An Enhanced CVD Approach to

Extensive Nanotube Networks With Directionality.

Adv. Mater.

, 12, 890-894.)

Clearly, the isolated-catalyst CVD method combined with electrode fabrication renders

abundant nanotube devices for further studies and provides a route to investigate growth

mechanisms and correlations between catalyst particles and nanotube structure (dis-

cussed in Section 12.2.3). Liu and his coworkers have developed a highly active Fe/Mo

catalyst by sol-gel synthesis for methane CVD growth of SWCNTs [20]. The high surface

area and large mesopore volume of this catalyst resulted in a nanotube-catalyst ratio as

high as 2:1 (1 g of catalyst yielding 2 g of SWCNTs). This is also an excellent example of

the scale-up of high-quality SWCNT synthesis that can be achieved by understanding

and optimizing the catalytic materials. Several groups have developed a gas-phase CVD

process to grow bulk quantities of SWCNTs [21-23]. Smalley and his coworkers [21] used

carbon monoxide as carbon feedstock and iron pentacarbonyl, produced by thermal

decomposition, as the catalytic source to achieve bulk production of SWCNTs.

Multi-walled carbon nanotubes have also been controllably obtained by the CVD

method in many research groups [24-27]. For example, Ren [24] has grown relatively

large-diameter and aligned “forests” of MWCNTs. Dai and coworkers [27] synthesized

aligned MWCNTs by CVD; here, the driving force for self-alignment is the Van de Waals

interactions between nanotubes, as shown in Figure 12.3.

Another significant advance in the CVD method for growth of CNTs is the use of alco-

hol. Maruyama and coworkers [28] recently reported the synthesis of highly pure

SWCNTs using alcohol. The authors attributed the high quality of the SWCNTs obtained

to the effects of OH radicals formed at high temperature, which can efficiently remove

amorphous carbon during nanotube growth. More recently, Iijima and coworkers [29]

found another method to produce extremely pure SWCNTs (purity 99.98%) by simply

adding water to ethylene during the CVD process, as shown in Figure 12.4. In this case,