Biomedical Engineering Reference

In-Depth Information

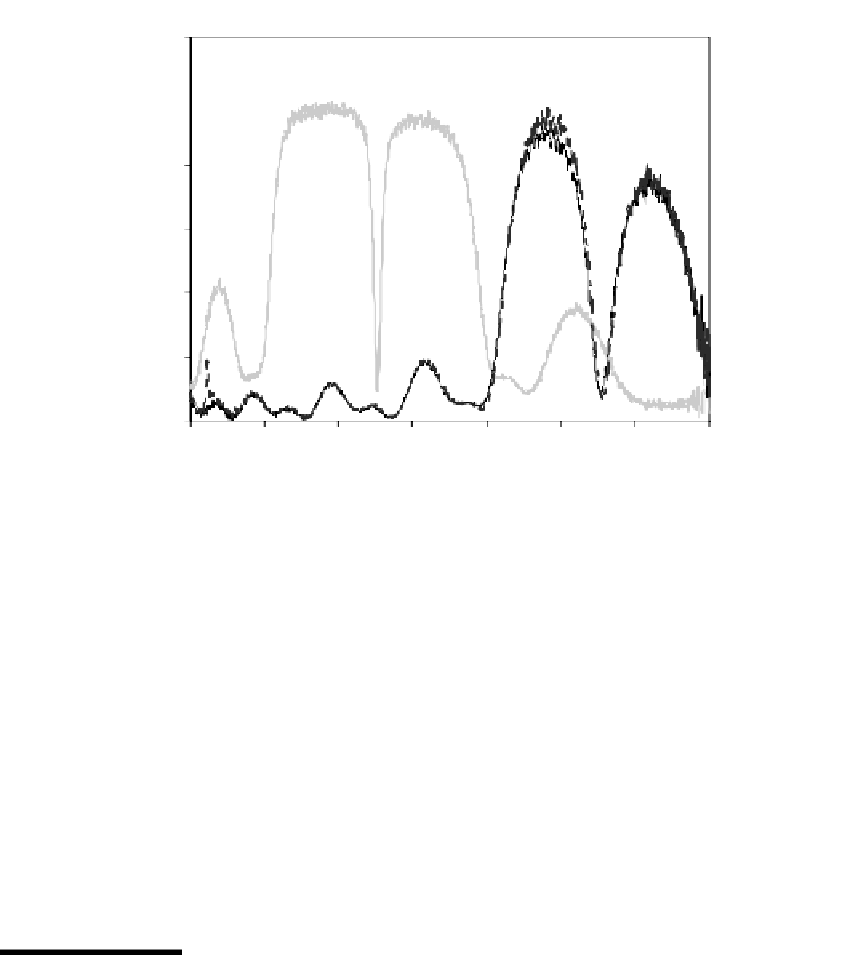

Before mounting

Mounted

3 days later

1 yr

120

100

80

60

40

20

0

600

650

700

750

800

850

900

950

Wavelength (nm)

FIGURE 11.12

Reflection spectra for a free-standing 5.2-

m thick microcavity membrane, before and after mounting in a hydro-

gel sheet.

process, allowing fabrication of microcavities. Two systems were examined to provide an

initial proof of concept for biosensing with these devices. First, chips were exposed to

varying concentrations of rabbit immunoglobulin G (IgG). IgG is a fairly large protein (150

kDa, or ~17 nm along its largest dimension) that does not infiltrate into mesoporous

microcavities well. However, a clear concentration dependence in the redshift of micro-

cavity response was available post-IgG exposure, indicating that infiltration of the protein

was facile. Second, biotin was covalently attached to the surface of a macroporous micro-

cavity, and used as a probe for streptavidin. Indeed, as one would expect, chips function-

alized with biotin showed a redshift after exposure to streptavidin, while those lacking

biotin did not.

11.9

Alternative Sensing Modes and Device Structures

11.9.1

“Smart Dust”

Building on their 1992 observation that ultrasonic treatment of PSi can produce suspen-

sions of luminescent particles,

42

Sailor and collaborators published two reports in 2002

detailing the use of such “smart dust” in chemical

43

and biological

44

sensing. We will

focus on the biological application here. PSi samples were etched as rugate filters, or

devices in which sinusoidal variation in the refractive index produces a narrow band of

high reflectivity (in this case, 11 nm) at a specific wavelength. Control over the precise

placement of this high reflectivity band allows for the production of “encoded” particles,

conceptually similar to the “smart beads” of Nie

45

or the infrared-encoded polystyrene

resins of Fenniri.

46