Biomedical Engineering Reference

In-Depth Information

produced by these devices.

10

Importantly, femtomolar sensitivity for DNA was reported,

and the device was also adaptable to the detection of other types of molecular targets. In

the subsequent work, Sailor and coworkers examined reversible binding of immunoglob-

ulin G (IgG) to a PSi surface covalently modified with protein A.

11

Derivatization of the

surface with protein A was found to reduce oxidative degradation of the PSi significantly.

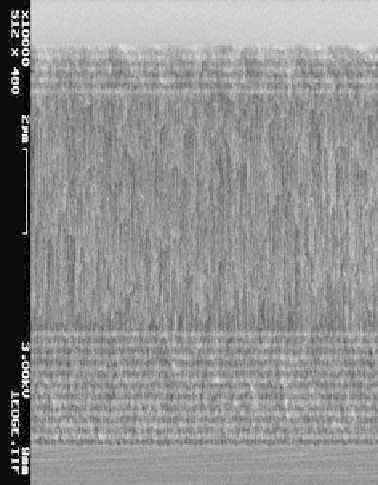

11.3

PSi Biosensors: Early Work at Rochester

In 1999, in collaboration with Philippe Fauchet's research group and initially also in col-

laboration with Prof. Lewis Rothberg, we began to examine the properties of an alterna-

tive device structure in the context of biosensing: the microcavity optical resonator. Such

a device consists of two Bragg mirrors (produced by repeating alternate high- and low-

porosity layers) on either side of a thick “active layer” of PSi (Figure 11.3). This geometry

provides a solution to the observation that controlling the size distribution of the

nanocrystalline silicon structures responsible for the material's luminescence is exceed-

ingly difficult. Instead of the large (>100 nm full width at half maximum (FWHM)) lumi-

nescence bands typically observed with single-layer structures, microcavity resonators

produce luminescence spectra with line widths typically FWHM less than 3 nm. Building

on methods developed for the production of multilayer PSi structures,

12

Fauchet's labora-

tory had initially described the fabrication of PSi microcavity devices in 1999.

13

In that

instance, the microcavity electroluminescence was used to produce what is essentially an

all-PSi light-emitting diode (LED). Importantly, this chapter verified that large changes in

porosity could be effected during the etch process (for highly doped

P

-type silicon wafers)

by changing the current density as a function of time. Since etching only occurs at the

interface between unmodified silicon and the etchant solution, structures remaining

behind are not modified further. This is not necessarily the case for alternative etchant

solutions or alternative substrate materials. Subsequent analysis of the geometry

Multilayer mirror

Active layer

FIGURE 11.3

SEM of a porous silicon microcavity.

Note that this particular example is

an asymmetric microcavity (differ-

ent number of mirror periods on

either side of the active layer), which

potentially increases the rate of

diffusion of analytes into the sensor.

Multilayer mirror