Biomedical Engineering Reference

In-Depth Information

reagents and operation by trained personnel, they are problematic as point-of-care diag-

nostic aids, and completely unsuitable for field-use as biosensors. Therefore, the need for

“label-free,” versatile, and simple-to-use sensing technologies has become starkly clear.

This chapter will cover the use of porous silicon (PSi) as the base material for a number of

such “label-free” sensors. Even though a significant amount of development work remains

to be done for PSi to be widely used in the field, the doctor's office, and the clinic, studies

by several groups (including ours) indicate that it shows considerable promise.

Our discussion on the development and current “state of the art” of PSi in biosensing

proceeds roughly chronologically. For the sake of brevity, we focus primarily on efforts at

the University of Rochester and by the Sailor and Ghadiri groups at the University of

California, San Diego (UCSD) and Scripps, respectively. However, we stress that many

other groups have made significant contributions to the development of this field.

11.2

Origins and Definitions

The initial discovery of PSi and early studies on its properties have been discussed at

length elsewhere,

5

and will not be covered in this chapter. Formed by anodic oxidation in

a solution containing hydrofluoric acid, PSi is exactly what its name implies: a mesh-like

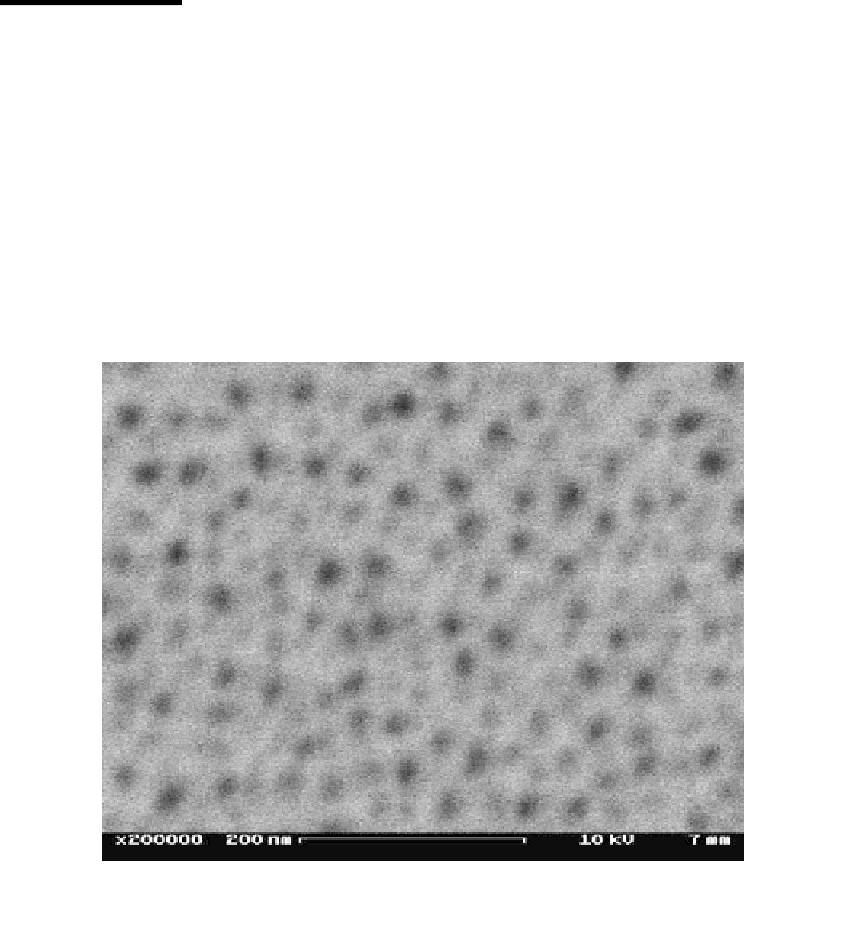

structure formed by partial dissolution of a silicon wafer (Figure 11.1). Porosity of the

material produced, defined as a percentage, is dependent on a number of factors includ-

ing the dopant level and type in the wafer, the concentration of HF in the etchant, and the

amount of current passed through the etch cell. The production of PSi is notable in that

conditions are chosen such that etching almost exclusively occurs only at the interface

between unmodified silicon and the etchant solution; once a porous structure has been

FIGURE 11.1

Scanning electron micrograph (SEM) of porous silicon.