Biomedical Engineering Reference

In-Depth Information

d

n

4

t

3

n

g

|

1

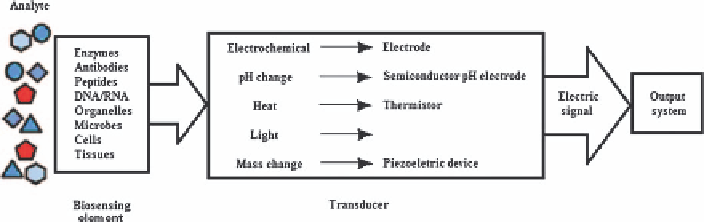

Figure 1.1

Schematic of typical components of biosensor architecture.

oxide sensor which responds to gases such as carbon monoxide.

1,2

In contrast,

biosensors are composed of a union between a transducer and biological/

biochemical receptor. A schematic of the structure including transduction types

is depicted in Figure 1.1. Note that the probe can consist of a variety of

biological entities ranging from antibodies to live biological cells Given that

nucleic acids and proteins are chemicals, as are the targets that cells as probes

are designed to detect, it is clear that the distinction between chemical- and

biosensors is artificial.

Crucial aspects of biosensor technology are the nature of the response of the

device with respect to time and whether ancillary chemistry is required in

addition to the basic probe in order to achieve a signal. With respect to the

former point, there are sensor specialists who take the view that such a device

must respond to its analyte in real time. Conversely, the field is often

considered to include 'one-test' disposable structures where there is no attempt

to conduct a measurement over a period of time, except in a repeated dipstick

fashion. The ubiquitous pregnancy and glucose test strips that are widely

commercially available constitute examples of this approach to biodetection.

The use of an adjunct chemical in addition to the receptor to achieve a

transducer signal is often termed tagging or labeling. An example of this

strategy is the use of dyes in conjunction with nucleic acid probes in order to

produce fluorescent signals.

3

In certain cases, there is insucient intrinsic

fluorescence in nucleic acid molecular probes to allow the direct possibility of

detection. The same is true for electrochemical methods where organometallic

complexes (of Ru) have to be employed for work with nucleic acids in order to

detect redox chemistry. Technology where such an approach is avoided is called

'label-free detection' and is often regarded to be attractive in view of the fact

that sensor fabrication becomes a somewhat simpler process.

Additional important technical factors are the possibilities for incorporation

of the device in flow-through automation, sensor miniaturization and

prevention of non-specific adsorption. Such automation involving standalone

systems avoids time-consuming personal intervention and allows rapid data

collection and validation. Microfluidic systems offer speed and saving of

reagent costs. Non-specific adsorption of unwanted components on the device

surface poses something of an Achilles' heel for biosensor technology. The

d

n

3

.