Geology Reference

In-Depth Information

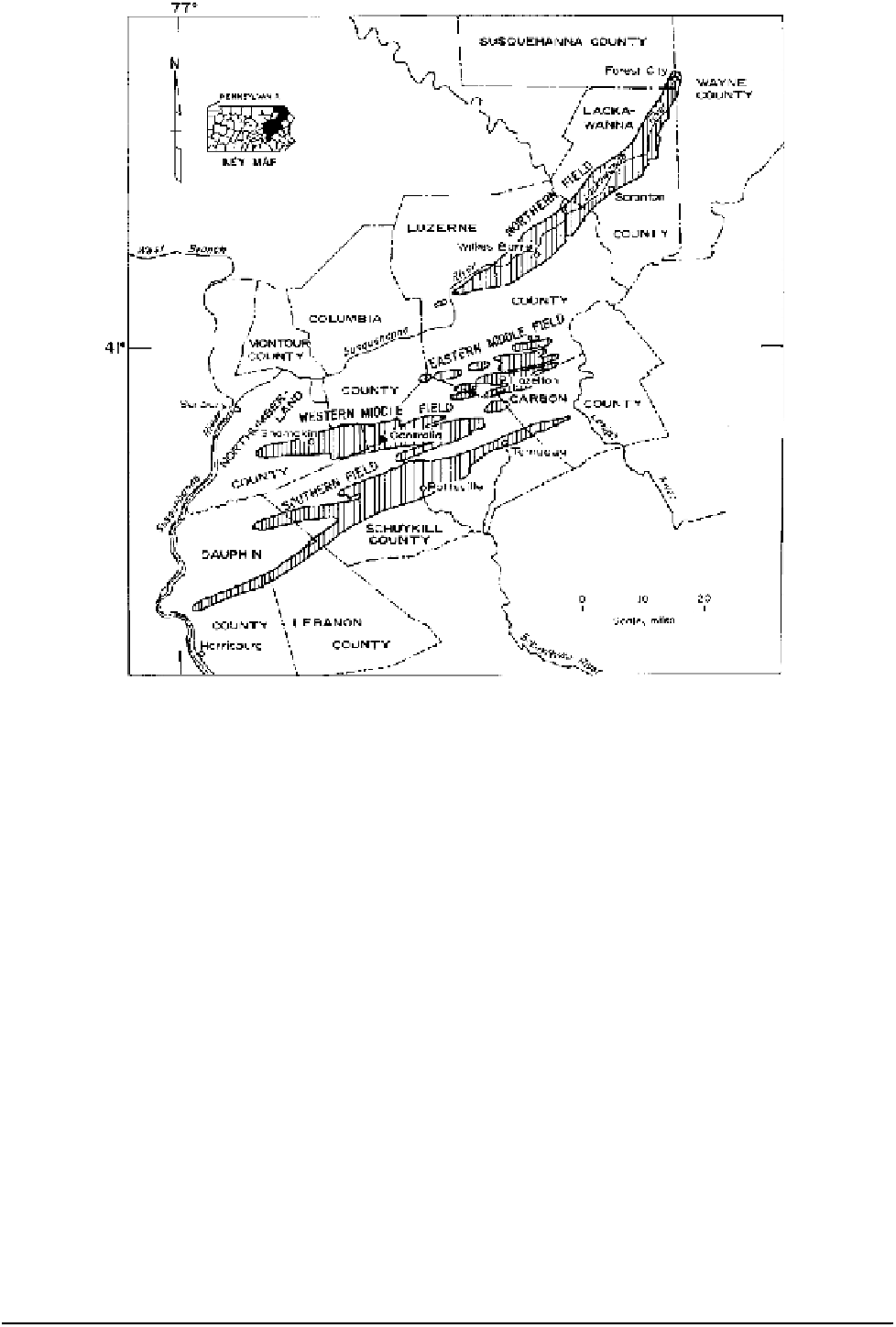

Figure 16.2.2. Map of anthracite coalfields in Pennsylvania. From Chaiken et al. (1983, p.3)

strip pits on the southern edge of the fire to reduce the amount of oxygen entering the mine. It would also include

exploratory drilling on the northern, eastern, and western edges to delineate the boundary of the fire. A temporary

flushed noncombustible barrier would be emplaced to constrain the fire while the second phase of the control

project was completed. Phase II consisted of excavating a permanent isolation trench on the cold side of the

flushed barrier. The depth of the trench was estimated at between 30.1 and 61.0m (100

-

200 ft). Phase I was

completed, but exploratory drilling indicated that the

fire had advanced further

than anticipated. Phase II would

now require an isolation

(300 ft) deep. As the first part of Phase II, an underground barrier

west of the fire would be constructed from the outcrop to the mine pool by injecting fly ash into the mine voids. In

1973, an underground flushed barrier was installed, but due to the depth, cost, and the amount of surface disruption

trench more than 19.4 m

Table 16.2.2

Number, average cost (US$1000), and estimated success rate (%) of US bureau of mines fire-control projects

in the anthracite fields between 1949 and 1978.

Method

Number of projects

Estimated effectiveness (%)

Average cost (US$1000)

Excavation

10

80

26 581

Flushing

14

43

5306

Surface Seal

2

50

41

Source

: Data from Chaiken et al. (1983).