Geology Reference

In-Depth Information

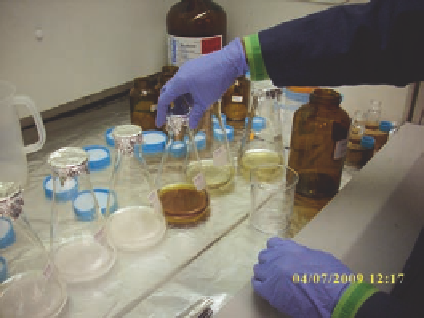

11.2. Sample Preparation

Organic solvent extraction in the

laboratory.

Photo Courtesy of Alpha Analytical Laboratory, Mansfield, Massachusetts, 2009.

Collection

T

he collection of coal and coal-tar samples for the analysis of semivolatile hydrocarbons is fairly simple. The

sample preparation and analysis can be completed with as little as about 5 g of sample; however, a nominal sample

size of ~100 g ensures the complete analysis by multiple methods including replicates, if needed. The conventional

sample container is a 4 oz (118.25mL) wide mouth amber jar with Teflon-lined cap that is devoid of organic

residues (US Environmental Protection Agency (USEPA), 2003). The samples are labeled with a unique sample

identity that often includes a code for the site, location, and depth interval. The samples are wrapped in packing

material (e.g., bubble wrap) and shipped to the hydrocarbon laboratory. Coal and coal tar do not require special

preservation; however, soil samples are commonly chilled to 2

-

6°C with ice that is sealed in a plastic bag. A chain

of custody is commonly completed to assure that the sample collection information (e.g., sample identities, date

and time of sampling, field team names, required testing methods, and custodial authority signature) is commu-

nicated to the laboratory. Upon receipt, the laboratory inspects the samples for damage during shipment and sample

preservation integrity, if applicable.

Extraction

S

amples of coal are extracted using a procedure developed for the extraction of semivolatile hydrocarbons

from highly sequestered soil and sediment (NOAA, 1993). The sample is initially subjected to particle size

reduction with mortar and pestle or equivalent to the approximate consistency of sand. Unless previously

determined, approximately 5 g of coal is weighed in an aluminum-weigh boat on an electronic balance

(

+0

.0001 g). After baking at 105°C for a minimum of 4 hours, the sample is re-weighed and percent moisture

determined by difference. A second aliquot of coal (~10 g) is placed in a solvent rinsed glass extraction vessel

(8 oz jars with Teflon-lined caps). An equal mass of anhydrous sodium sulfate (Na

2

SO

4

) is added to remove

residual moisture. The sample is spiked with a mixture of surrogate compounds that demonstrate the sample

extraction efficiency. Thirty to sixty milliliters (mL) of DCM are added on top of the spiked and dried sample.

The vessel is sealed and agitated on a shaker table for a minimum of 12 hours. The first extract is decanted

through a powder funnel containing anhydrous Na

2

SO

4

and collected in an Erlenmeyer flask. The extraction

vessel is recharged with DCM (30

60mL) and extracted a second time on the shaker table for at least 1 hour.

After decanting, the extraction vessel is recharged with DCM (30

-

-

60mL) and extracted a third time on the

shaker table for at least 1 hour. The combined DCM extract is concentrated by Kuderna Danish apparatus to

less than 10mL. The sample is brought up to exactly 10mL in a calibrated graduated cylinder. A small aliquot

is removed to determine the TEM.

Coal-tar samples are homogenized in the sample collection container with a laboratory spatula. Approximately 2 g

are transferred to a dilution vessel (10mL scintillation vial or equivalent) with Teflon-lined cap. Approximately

4mL of DCM are added to the vial. The vessel is capped and shaken by hand, votexed, or sonnicated for ~2

5

minutes. The sample is filtered through a power funnel containing anhydrous Na

2

SO

4

that drains into a 10 mL

-