Geology Reference

In-Depth Information

exposed to the gas. Several tiles were sent to my lab, where the minerals were removed and identified by X-

ray diffraction as gypsum and orthorhombic sulfur-8. In addition, several tiles were emplaced in 2004 and

2005 over gas vents associated with the Centralia fire (Figure 9.2.6B). The results were unsuccessful, as the

tiles were removed and tossed on the ground by visitors to the mine fire. Furthermore, the minerals collected

from such tile experiments are now questionable in origin. They may not actually be condensates but instead

the reaction products of gas with the tile substrate, as was analogously demonstrated by Stracher et. al.

(2005a) for coal-fire minerals collected from a quartzofeldspathic sandstone substrate in the Wuda coalfield

of Inner Mongolia.

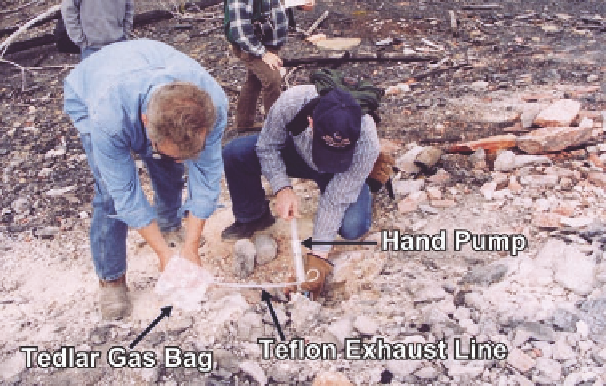

Gas-Collecting Techniques

F

or complete laboratory analysis of gas exhaled from coal-fire vents and fissures, two collection techniques have

been used. The first technique, no longer used, uses a Tedlar

®

gas bag made of Dupont

TM

Teflon

®

connected to a

LaMotte (or other manufacturer) air sampling pump and Teflon

®

intake and exhaust lines (Figure 9.2.7) for

pumping gas out of a vent or fissure and into the collection bag. This pump illustrated delivers 50ml per stroke and

the bags hold 600 ml, so 12 strokes fill a bag. The bags have a swage lock used to seal the gas inside. A circular

disk 3mm in diameter on the side of the bag is used to insert a hypodermic needle and extract the gas for analysis.

If a vent is hot enough to melt the Teflon

®

tubing, gas may still be obtained by working quickly. Although glass

storage vials are available, I initially used Tedlar

®

gas bags because they are compact to store and do not break

easily.

The current collection technique for coal-fire gas uses stainless steel gas canisters and a stainless steel intake line

(Figure 9.2.8). Laboratory tests have shown the stainless steel canisters to be more reliable than Tedlar

®

bags in that

the bags tend to be permeable with respect to coal-fire gas over a storage period of 2 weeks or more.

The stainless steel canisters are evacuated; contain a valve on the top and a fitting into which one end of a stainless

steel gas extraction line is inserted. The other end of the line is then inserted into a vent or fissure. When the valve is

opened, a

sound is heard as the coal-fire gas enters the canister. After the noise ceases, the valve is

then closed and the sample collecting procedure is completed. The sample is then sent to a laboratory for gas

chromatographic analysis.

“

whooshing

”

Figure 9.2.7. Tedlar

®

bag, gas collection technique, Centralia, Pennsylvania. Glenn B. Stracher (right) pumping

coal-fire gas from a vent through a Teflon

®

exhaust line into a Tedlar

®

gas bag, held by Tim Nolter (left). The

intake line in Stracher

s left hand (leather glove) extends several centimeters down into the gas vent. The gas

temperature measured there with a thermocouple probe was 363°C. From Stracher et al., 2007, with modifications,

permission of the Geological Society of America.

'