Geology Reference

In-Depth Information

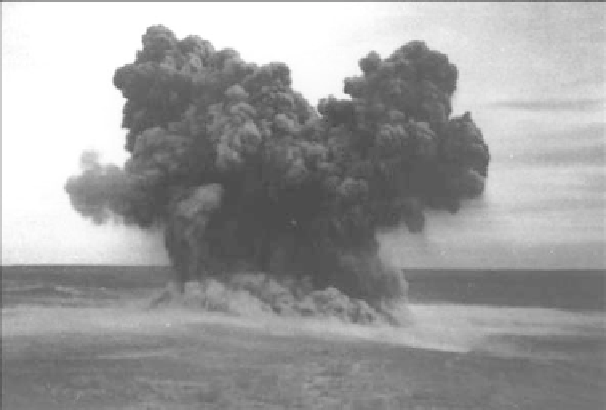

Figure 5.1.3. Controlled-directional blasting used to extinguish an underground coal-mine fire, Beishan coalfield,

Qitai County, China. Reproduced with permission of Taylor & Francis. After Bell and Donnelly 2006; photo by

Bell 1985.

Opencast Sites

At present, there is no completely reliable and successful method for the control and prevention of spontaneous

combustion of coal seams in opencast mines. However, in the Singrauli coalfield, India, the authors observed

combustion control using fire-prevention techniques (Bell and Donnelly, 2002, 2006). The techniques consisted of

the following procedures. Soon after stripping the overburden, the coal and associated rocks were cleaned using a

powerful water-jet hose. This served a dual purpose. The first was to remove any loose rock debris choking areas

where air would be trapped and the second was to cool the coal and nearby rocks. The coal and other rocks were

then sprayed with a liquid-bitumen-based compound that temporarily seals fissures where air could penetrate and

promote combustion. After about one year, the coal seam was extracted. This method has been used in India with

varying degrees of success. However, an adverse secondary effect of this technique is the generation of large

quantities of steam and ash, observed by one of the authors to present a nuisance to workers within the opencast

mine and surrounding areas (Figure 5.1.4).

Colliery Spoil Heaps

The spontaneous combustion of coal in colliery spoil heaps may be reduced if oxygen is prevented from mixing

with the waste and if there is an excess of moisture to contain any heating that may occur.

For spontaneous combustion to occur in colliery spoil, three things must be present. These are a substance with

sufficient calorific value to support combustion, a continual supply of air (oxygen), and a source of ignition. If one

or more of these are absent, then there is no potential for combustion to occur (Bell and Donnelly, 2006).

It was suggested by Cook (1990) that the emplacement of layers of compacted colliery discard on a spoil heap may

prevent or smother combustion by preventing air ingress. This blanketing technique, along with trenching, the

injection of non-combustible materials (e.g., pulverized fuel ash), and spraying with water potentially reduce the

risk of self-heating (Anon, 1973; Bell, 1996). Compacting with discard, although potentially effective in reducing

air flow into colliery spoil, must be done cautiously since this may induce collapse or subsidence if shallow voids

exist in the burnt spoil.

Temperature monitoring in boreholes may be used to verify and monitor the migration of a burning front within a

colliery spoil (Nottinghamshire, England example, below). Furthermore, loss-on-ignition tests may be undertaken

and compared with threshold limits (Richards et al., 1993). These range from 2MJ/kg (unlikely to burn) to 10MJ/kg

(almost certainly combustible) (Interdepartmental Committee on the Redevelopment of Contaminated Land

(ICRCL), 1986).