Information Technology Reference

In-Depth Information

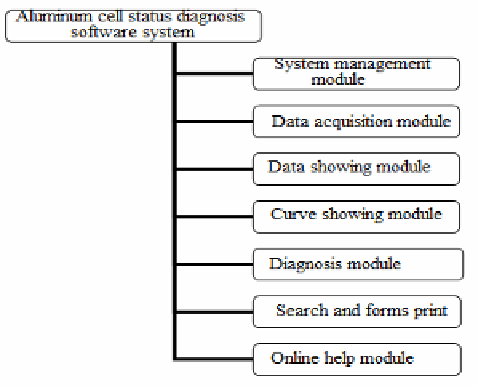

Figure 4 is the components of the system. We use the 30 sets of data acquired on site to

test the well-trained BP neural network. As a result, 25 sets of them could diagnose the

status correctly. That is to say the accuracy rate could reach 83. The accuracy of this

cell diagnosis model is verified.

Fig. 4.

System function module chart

5 Conclusion

1. According to the characteristics of the aluminum production cells status and the

production system at present, we accomplish an overall design for the system.

2. Neural network is used to establish the cell status diagnosis model. Also genetic

algorithm is applied to optimize the initial weights and threshold value of the BP neural

network.

3. After testing this system with the actual production data. We can find that the

diagnosis result is consistent with the actual situation.

Acknowledgment.

Project supported by the National Natural Science Funds (Based on

the Six Sigma and Trend of Sequential Pattern of Aluminum Cell Condition

Forecasting Model and Algorithm for Research Funding: 51075423).

References

1.

Liu, Y., Li, J.: Modern Aluminum Production. The Metallurgical Industry Press, Beijing

(2008)

2.

Zeng, S., Li, J.: Model Predictive Control of Superheat for Prebake Aluminum Production

Cells. Light Metals (2008), TMS Annual Meeting (March 2008)

Search WWH ::

Custom Search