Graphics Reference

In-Depth Information

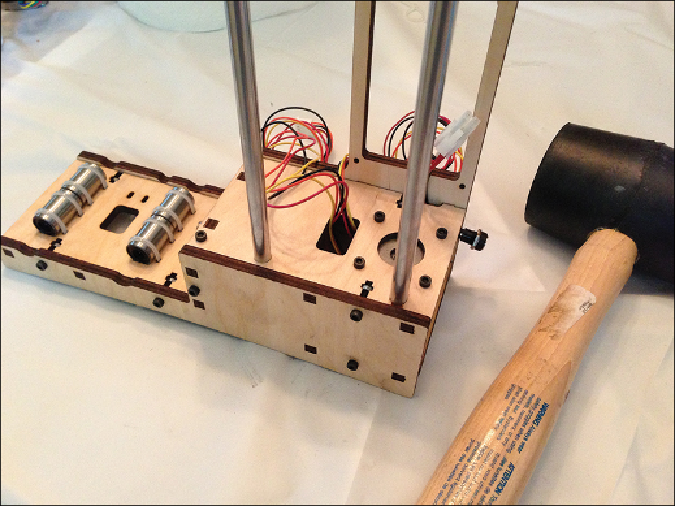

Midway Through Assembly Observations

When it comes to the two 10” metal rods, you need to be very careful when insert-

ing them through the cut holes. The instructions recommend using a hammer or a

rubber mallet, and I highly recommend the rubber mallet option. The keys to this

step are to hold each rod perfectly vertical as you hammer it into the circular hole.

You're going to feel resistance because the holes are slightly smaller in diameter

because the rods must be held securely and tightly for the Z-axis to work properly.

You can see in

Figure 3.10

that I was successful in getting both metal rods inser-

ted; pay attention to the instructions that tell you to place some extra wood pieces

underneath the bottom of the base so it doesn't crack.

Figure 3.10

The Z-axis metal rods are inserted.

Next, use zip ties to connect the bottom X-axis plate shown in

Figure 3.11

to the

two 6.5” metal rods inserted into the X-axis bearings. These rods should move left

and right easily, with almost no resistance. Pay attention to how the nubs of the

zip ties rest on top of this plate and not the bottom. You also want to make certain

the small hole on the plate is on the left (when looking from the front). This hole

Search WWH ::

Custom Search