Biomedical Engineering Reference

In-Depth Information

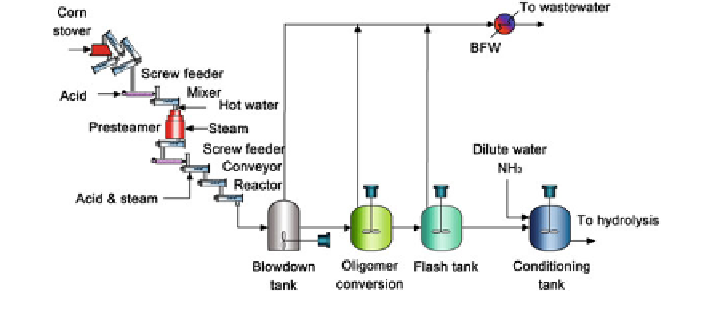

Fig. 7

Process diagram of the NREL projected dilute-acid pretreatment of corn stover [

28

]

acid is added at the discharge point at a concentration of 18 mg/g dry biomass

before feeding into the horizontal reactor, which is operated at 158C (0.55 MPa),

with a residence time of 5 min. The feedstock from the horizontal reactor is

discharged into a blowdown tank operated at 130C (0.28 MPa). The slurry from

the blowdown tank goes into the oligomer conversion tank, where an additional

4.1 mg acid/g feedstock is added, making the total acid loading 22.1 mg/g dry

biomass. The oligomer conversion tank is also maintained at 130C, with a resi-

dence time of 20-30 min. Subsequently, the feedstock is discharged into a flash tank

operated at atmospheric pressure. At this stage, the hydrolysate containing 30% total

solids and 16.6% insoluble solids is pumped into the conditioning tank, in which the

slurry is diluted to slightly higher than 20% total solids for enzymatic hydrolysis and

cooled to 75C. Ammonia is sparged into the dilution water to adjust the hydrolysate

pH to 5 as well as to provide a nitrogen source for subsequent microbial growth and

ethanol fermentation. All volatile components from the blowdown tank, oligomer

conversion tank and flash tank are condensed and collected [

29

].

Although dilute acid pretreatment seems more economically competitive, some

disadvantages like corrosion, which requires expensive acid-resistant stainless

steel or coatings, and inhibitors produced during the pretreatment under high

temperatures, have led to the exploration of alternatives, one of them being

alkaline pretreatment. Various alkalis including sodium hydroxide, lime and

aqueous ammonia have been studied [

30

-

32

]. Basically, alkaline pretreatment is a

delignification process, and the underlying mechanism is the saponification of

intermolecular ester bonds crosslinking xylan hemicelluloses and lignin [

33

].

In addition, alkaline pretreatment also removes acetyl and other acidic substitu-

tions on hemicelluloses that protect cellulose from attack by cellulase [

34

].

Moreover, alkaline pretreatment causes swelling of the lignocellulosic biomass,

leading to the decrease of DP and crystallinity of cellulose and increase of the

surface area to facilitate the enzymatic hydrolysis of cellulose. The effectiveness of

alkaline pretreatment depends on the characteristics of lignocellulosic biomass

and reaction conditions. In general, alkaline pretreatment is more efficient with

herbaceous crops and agricultural residues with relatively low lignin content.

Search WWH ::

Custom Search