Biomedical Engineering Reference

In-Depth Information

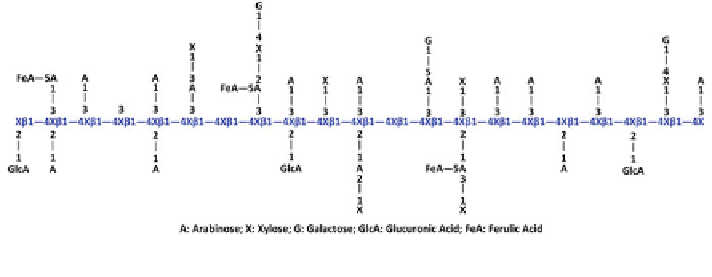

Fig. 1

Schematic structure of corn fiber heteroxylan (modified from [

11

,

16

])

In general, hemicellulose can be hydrolyzed to its sugar constituents by

chemical or enzymatic processes. The chemical hydrolysis of hemicelluloses is

much easier to accomplish than the hydrolysis of cellulose, due to the heteroge-

neous structure and composition of hemicelluloses and its low degree of

polymerization and low crystallinity [

17

]. Generally, the first step of hemicellu-

lose-based fuel or chemical production is lignocellulose pretreatment, and different

pretreatment methods have been developed. In most cases, hemicelluloses are

commonly removed during the initial stage of biomass processing, aiming to

reduce structural constraints for further enzymatic cellulose hydrolysis (Fig.

2

)

[

18

,

19

]. The main process options for the selective fractionation of hemicelluloses

from biomass include the use of acids, water (liquid or steam), organic solvents,

and alkaline agents (Table

2

)[

20

]. The last two are not selective towards hemi-

cellulose as they also remove lignin, which in turn can hinder the fermentation or

bioconversion process of the hemicellulose sugars. Therefore, acid/water/steam

pretreatments are the most commonly applied technologies, yielding a selective

solubilization of hemicelluloses and producing hemicellulose-rich liquids totally

or

partially

hydrolyzed

to

oligomeric

and

monomeric

sugars

and

cellulose-

enriched solids for further bioprocessing.

Many acids are known to be good hydrolytic agents. The common method of

acid hydrolysis uses dilute acid [

21

]. Dilute sulfuric acid hydrolysis has proved to

be a favorable method for pretreatment before enzymatic hydrolysis and also for

the conversion of hemicellulose to sugars [

22

-

24

]. One of the earliest commercial

hydrolysis processes was a dilute sulfuric acid process carried out at a relatively

low temperature for a prolonged period of time. Recently, a great deal of research

has examined the dilute acid hydrolysis of woods and agricultural residues to

produce sugars. During acid hydrolysis of hemicellulose, pentoses are degraded

rapidly to furfural and condensation byproducts [

21

]. These compounds may also

inhibit the later fermentation processes, leading to lower yield and productivity,

and a prior detoxification treatment might therefore be required. In order to prevent

the decomposition of sugars, especially pentose, a more dilute acid, a shorter

reaction time, a lower temperature, and the rapid removal of hydrolytic agents are

required.

Search WWH ::

Custom Search