Biomedical Engineering Reference

In-Depth Information

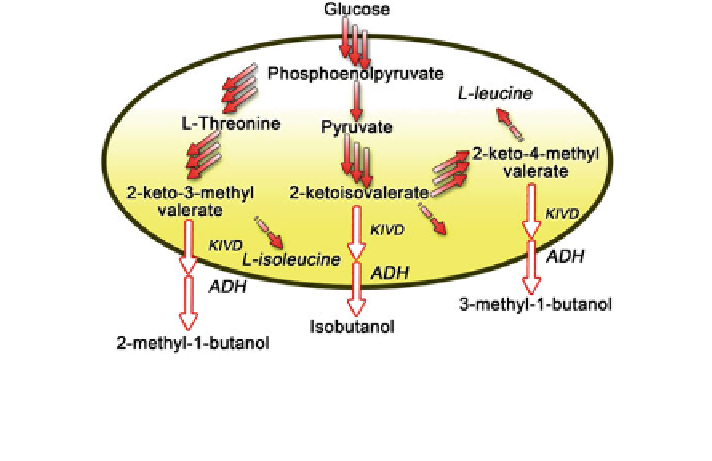

Fig. 4 Synthetic pathway and key enzymes for production of isobutanol, 3-methyl-1-butanol

(isopentanol), and 2-methyl-1-butanol. When 2-keto acid decarboxylase (kivd) and alcohol

dehydrogenase (ADH) are introduced, the 2-keto acid intermediates of

L

-valine,

L

-leucine,

and

L

-isoleucine biosynthesis are directed for the production of isobutanol, 3-methyl-1-butanol,

and 2-methyl-1-butanol

catabolic and anabolic pathways involved in de novo synthesis of branched-chain

amino acids through their biosynthetic pathways from glucose.

As an alternative to the petrochemical production, isobutanol can also be pro-

duced from renewable bio-based feedstocks by metabolically engineered microor-

ganisms. The team led by Liao [

28

] made great progress in constructing the synthetic

pathway for isobutanol production in E. coli as well as C. glutamicum. The

engineered strain produced 22 g/L isobutanol after 112 h [

28

]. This team also

engineered a C. glutamicum strain which can produce 4.9 g/L isobutanol [

51

]. To use

lignocellulose as the feedstock for isobutanol production, Liao and his colleagues

[

52

] successfully engineered Clostridium cellulolyticum for direct conversion of

cellulose to isobutanol through the process of consolidated bioprocessing. The US

Department of Energy's BioEnergy Science Center (BESC) at Oak Ridge National

Laboratory also developed the technology for isobutanol production directly from

cellulose.

Some researchers have used Cyanobacteria for isobutanol production, since

these organisms can use carbon dioxide as the feedstock. Heterologous expression

of valine synthesis enzymes has been used to convert pyruvate to ketoisovalerate

within Synechococcus elongatus PCC 7942. Intracellular ketoisovalerate is then

converted to isobutyraldehyde at a rate of 6.23 mg/L/h by coexpression of the keto

acid decarboxylase gene. Isobutyraldehyde is further converted to isobutanol by

coexpression of alcohol dehydrogenase from E. coli. Isobutanol was recovered

from the liquid phase in about 50% yield [

53

].

Two research groups in China have also been engaged in engineering micro-

organisms for isobutanol biosynthesis. The team led by Jianping Wen of Tianjin

University [

42

,

54

] engineered B. subtilis 168 for isobutanol production through

Search WWH ::

Custom Search