Biomedical Engineering Reference

In-Depth Information

C

' (dimensionless)

1

0.95

0.9

0

2

4

6

8 10

X

' (dimensionless)

12

Oxygen concentration on the pore axis

Analytical 1 D approach

Variation in oxygen concentration

on the pore surface

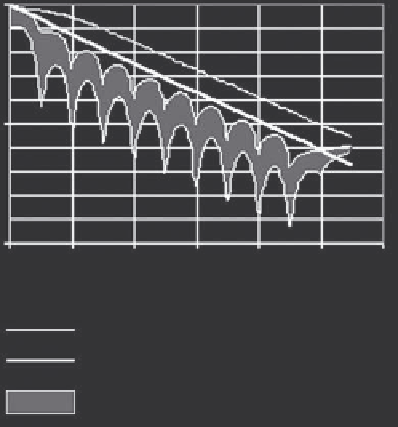

FIGURE 3.12

Longitudinal distribution profile of the dimensionless oxygen concentration

in the representative elementary volume of the pore channel. Comparison

between one- and three-dimensional modeling approaches shows that, under

the assumed experimental conditions and at the scale of the overall pore

length, the transport phenomena are convection dominated. The variation

in local surface distribution of the feeding oxygen concentration (gray shaded

area) is mainly due to the presence of stagnation zones in the vicinity of the

close contact between two adjacent fibers.

mechanical stimulation (0, 0.1, and 1.0 dyne cm

−

2

viscous shear stress depend-

ing on the flow rate). In this framework, a mathematical model of oxygen

transport within the dual chamber parallel-plate bioreactor presented in Fig-

ure 3.13 was defined and numerically solved (Pierre et al

.

2008).

The parallel-plate bioreactor (Gemmiti and Guldberg 2006) is constituted

of three distinct domains: a tissue-engineered rectangular slab of cartilage,

which is enveloped by an upper chamber in which the media flows, and a

lower chamber which acts as a reservoir of nutrient. Via the control of nutri-

ent media flow rate in the upper chamber, different mechanical stimulation

of cells were applied to obtain a tissue construct with mechanical proper-

ties (Young's modulus, ultimate strength) and matrix composition approach-

ing those of natural cartilage. The question is then to know if varying the

flow rate in the bioreactor consequently leads to a significant and quantifi-

able change in the oxygen feeding of the cells embedded in the engineered

tissue.

Search WWH ::

Custom Search