Biomedical Engineering Reference

In-Depth Information

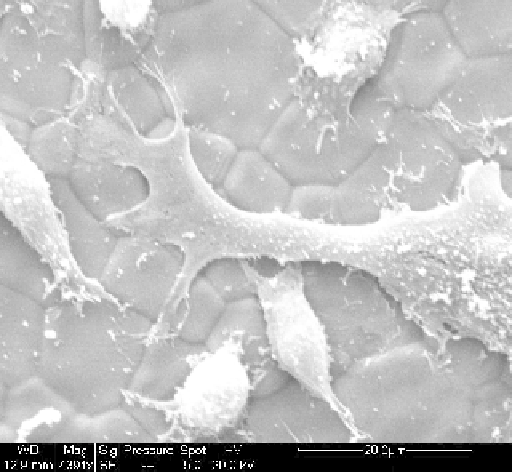

Figure 3.4.

Mouse fi broblast (L929) cell adhesion on thermally etched hydroxyapatite surface

showing no such difference in cell adhesion on grain and grain boundary region.

another material to develop bulk composite material with good mechanical prop-

erties (see Table 3.1) or used as a coating on biomaterial. Some examples are

hydroxyapatite coating on metal

21,22

, alumina - hydroxyapatite composite

23,24

, zir-

conia hydroxyapatite

25,26

composite. In the last decade, researchers have attempt-

ed to develop biocomposites by combining bioactive HAp with bioinert ceramic

phase, like Al

2

O

3

or ZrO

2

.

3.4.2 Hydroxyapatite-Ceramic Composites

Zirconia, irrespective of its morphology and phase composition, did not induce

the decomposition of hydroxyapatite matrix in the hot pressed HAp-ZrO

2

composites

27

. Improvements in toughness and strength achieved for HAp-ZrO

2

composites were not accompanied by an increase in the Weibull modulus (an

indicator of strength reliability for brittle ceramics). In a different study, HAp-

Al

2

O

3

composites of functionally graded structure can be fabricated by the un-

derwater-shock compaction technique without the use of any sintering-aid

28

. The

composite showed continuous compositional variation after heat treatment up to

1200 ° C. Hill and Clifford observed that HAp decomposes at 950 ° C

29

and accord-

ingly, sintering experiments were carried out using fl urohydroxyapatite (FHA),

while replacing HAp. It was found that FHA has better thermal stability than

HAp and it can be sintered at 1400 °C

30

with 40% ZrO

2

without dissociation. Also,

the biocompatibility of FHA is comparable with pure HAp.

Search WWH ::

Custom Search