Biomedical Engineering Reference

In-Depth Information

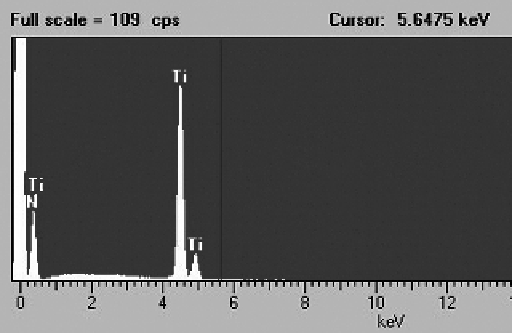

Figure 21.1.

Energy Dispersive X-ray spectra (EDX) of TiN surface showing peaks correspond-

ing to titanium and nitrogen elements.

comparison of the profi les of the sample surfaces before and after coating revealed

that there is marginal deterioration in surface fi nish while coating polymer

samples. While in the case of metal substrates the surface fi nish of the substrate

was more or less retained after the coating process (see Figure 21.2 and Table

21.4). These measurements correlated well with the surface roughness measure-

ments carried out using mechanical contact profi lometry (Surtronic 3+, Rank

Taylor Hobson Ltd, UK).

21.7.2 Adhesive Wear Characteristics

A pin-on-wheel test system is used for studying the adhesive wear properties of

the material combinations. It consists of platform rotating at a constant speed of

60 rpm and a pin loading arm for provisions for applying a constant load on the

pin. The wheel diameter is 25 mm on which the pin with 3 mm diameter contact

area is allowed to traverse in circular motion [Muraleedharan et al., 1989]. The

test conditions are described in Table 21.5.

Results from the study (see Figure 21.3) show that both DLC and TiN coat-

ings improve the wear characteristics substantially. Moreover, the wear tracks on

the UHMWPE surface is found to be more uniform and with less cracks when

articulated against coated surfaces than with uncoated metallic surfaces. The

weight loss from UHMWPE was lowest when DLC-coated pin is used as the

counter face; but TiN surface generated a smoother worn surface with minimal

track marks and best surface fi nish (see Figure 21.4 ).

UHMWPE wheels used had initial surface fi nish of the order of 0.15

m Ra.

The wear tracks generated by titanium, DLC coating, and TiN coating were

having surface roughness values of 0.47

μ

μ

m Ra, 0.16

μ

m Ra, and 0.08

μ

m Ra,

respectively.

Search WWH ::

Custom Search