Biomedical Engineering Reference

In-Depth Information

H

3

O

+

(a)

Ca

2+

O

Si

O

Al

O

Si(OH)

4

silica gel layer

AI

3+

, Ca

2+

cations

for crosslinking

(b)

Ca

2+

Glass

AI

3+

C

PO

4

3-

-

O

O

F

-

Ca

2+

+

H

+

O

O

-

Reacted glass with

silicious gel coating

C

C

Lonically crosslinked poly (salt)

cement matrix containing

anions and cations

HO

O

Poly (acrylic acid)

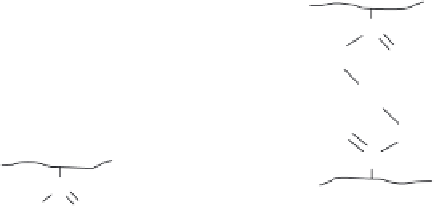

Figure 12.1.

Schematic illustration of A: acid degradation of an alumino-silicate network and

B: setting reaction in a glass ionomer cement [2].

form is usually a coarse glass frit that results from the quenching of the melt

either onto a metal plate and then into water or directly into water. The glass is

then ground further by dry milling in a ball mill or a gyro mill to a particle size less

than 45

m for a fi ne grained lutting

cement. The main criterion for the design of the glasses is their basic character

that would compensate for the low acidity of polyacrylic acid. Often, the reactiv-

ity of the glasses needs to be reduced by etching of the glass particles with 5%

aqueous acetic acid or annealing of the glass at temperatures in the range of

400 °C to 600 °C depending on the composition. There is a large number of

ionomer glass compositions that have been studied as cement formers. An impor-

tant advantage of the ionomer glasses is that under appropriate heat treatments,

they crystallise into an apatite phase that makes the glass-ceramics biocompatible

and promising for use in restoring and replacing hard tissues in orthopaedic and

dental fi elds. Hill et al. developed a series of glasses that crystallise into needle-

like fl uorapatite and mullite phases that interlock with each other giving rise to

high fracture toughness values [10, 11].

This chapter aims to give an overview of the structure of ionomer glasses

starting from the design of the glasses and fi nishing with the characterisation

μ

m for a fi lling grade cement or less than 15

μ

Search WWH ::

Custom Search