Biomedical Engineering Reference

In-Depth Information

0

-0.4

-0.8

-1.2

-1.6

RFSC

BioSC AXIAL

-2

BioSC RADIAL

-2.4

RBSC

-2.8

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

SiC Volume fraction

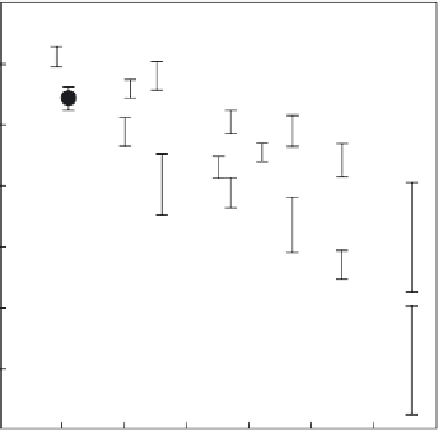

Figure 11.16.

Plot of the relative strength versus the volume fraction of SiC for the silicon-

ized SiC ceramics studied in this work. For every material, the average of the relative strength

at different temperatures was taken. See text for further discussion.

orientation of the SiC cells on the high strength of the material. RFSC have a

strength that is roughly the average of the axial and radial strength of BioSiC, and

RBSC has a signifi cant lower strength than the other two types of siliconized SiC.

The curves of the axial BioSiC and RBSC (materials with the best and worse

strength) are displaced roughly 20% on SiC content for the same strength.

In summary, the mechanical properties of biomorphic SiC with microstruc-

ture suitable of medical applications are very promising. The room-temperature

compressive strength in the longitudinal (biological precursor growth) direction

of sapelli-derived bioSiC is from 1160

±

100 (s.d.) MPa to 210

±

20 (s.d.) MPa, and

in the radial direction is from 430

10 (s.d.), depending on

the amount of silicon removal, that can be controlled by thermal or chemical

etching. These results compare positively with the compressive strength of a

typical human cortical bone: 193 MPa in the longitudinal direction and 133 MPa

in the radial direction [Gibson, 1973]. The absolute values of strength are in the

same range that the lowest values of bioSiC, being their density range very similar

(density range of cortical bone 1,6-2,0 g.cm

− 3

) [Gibson, 1973]. The room tempera-

ture bending strength of bioSiC ranges from 430

±

50 (s.d.) MPa to 120

±

20 MPa in the

density range of 2.3 to 2.0 g.cm

− 3

[Presas, 2005]. Elastic modulus range from to 25

to 230 GPa depending on the amount of silicon removal [Smirnov 2003, Kaul

2006], so this property can be modelled close to the value of the elastic modulus

of cortical bone (15

±

60 to 150

±

±

5 GPa) [Gibson, 1973 ]. The fracture toughness reach values

Search WWH ::

Custom Search