Biomedical Engineering Reference

In-Depth Information

300

Beech (axial)

Poplar (axial)

Mahogany (axial)

Red oak (axial)

(a)

250

Sapele (axial)

200

MSA model

UDP

150

NUDP

100

50

0

40

45

50

55

60

65

Porosity (%)

120

(b)

Beech (radial)

Poplar (radial)

Poplar (tangential)

Mahogany (radial)

Mahogany (tangential)

Red oak (radial)

Red oak (tangential)

100

80

Sapele (radial)

Sapele (tangential)

60

MSA model

40

20

0

40

45

50

55

60

65

Porosity (%)

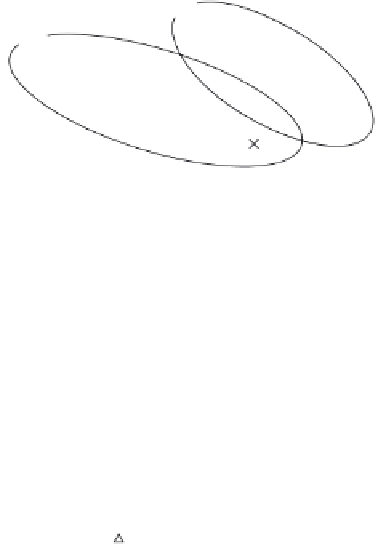

Figure 11.15.

Elastic modulus as a function of porosity for: (a) axial; and (b) tangential and

radial orientations with UDP and NUDP bioSiC grouped in the axial plot (error bars equal one

standard deviation). Values predicted by the MSA model for both orientations are shown by

dashed lines.

materials is plotted as relative strength,

σ

c

/

σ

ys

(where

σ

c

is the strength of the

porous solid and

ys

is the strength of the fully dense material), versus SiC volume

fraction. The strength data of the fully dense sintered SiC, measured under the

same experimental conditions, is taken from a previous work [Muñoz, 2002]. For

every material, the average of the relative strength was taken, and the scatter is

indicated with the error bars. The compressive strength of BioSiC was measured

in the axial and radial orientation. It was up to six times larger when the com-

pression was parallel to the axial direction, indicating the importance of the

σ

Search WWH ::

Custom Search