Biomedical Engineering Reference

In-Depth Information

1600

400

6

Eucalyptus

(a)

(b)

1400

Axial

Radial

5

Eucalyptus

1200

300

Maple

4

1000

800

200

3

Beech

600

2

Maho.

400

100

Beech

1

200

Beech

Beech

0

0

0

0

2.1

2.2

2.3 2.4

2.5

2.6

2.7

0

2.1

2.2

2.3 2.4

2.5

2.6

2.7

Density (g/cm

3

)

Density (g/cm

3

)

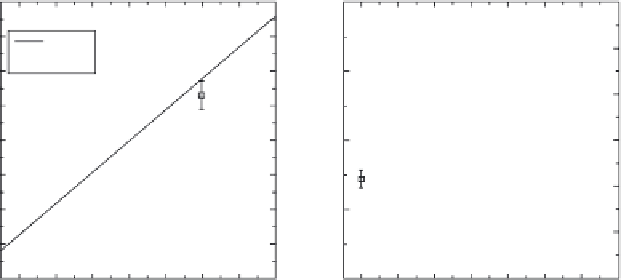

Figure 11.12.

Ambient temperature mechanical properties of the biomorphic Si/SiC com-

posites: (a) compressive strength; (b) fl exure strength measured in four-point (solid lines and

symbols) and fracture toughness (open circles and broken line).

2002 ; Presas, 2005 ; Presas, 2006 ; Kaul, 2006 ; Smirnov, 2003 ; Kardashev, 2005 ;

Kardashev, 2006; Gutierrez-Mora, 2005]. This section presents the results more

directly related to the use of this material as medical implant.

The mechanical properties of the biomorphic composites at ambient tem-

perature are plotted as a function of density in Figure 11.12. [Presas, 2005]. The

axial compressive strength (Figure 11.12a) of the Si/SiC composites was a linear

function of the density, and this is in agreement with previous results on the com-

pressive strength of biomorphic Si/SiC manufactured from pyrolyzed poplar and

obeche [Singh, 2002], in which the porosity was also the main factor controlling

the strength. Of course, the particular microstructure of the biomorphic compos-

ites, inherited from the precursor woods, was responsible for the anisotropy in

the compressive strength along the axial and radial directions in beech (Figure

11.12a), and thus the oriented microstructure of the biomorphic composites

provide optimized properties when loaded along the trunk axis. But the results

indicate that the main factor controlling the axial compressive strength was the

biomorphic density (or, inversely, porosity) rather than the actual precursor

wood.

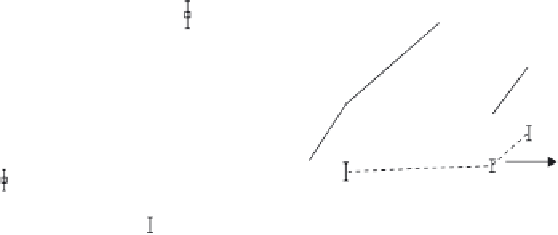

The behavior in bending and fracture is plotted in Figure 11.12b and shows

that the strength and toughness of the beech-based biomorphic composite with

low density (2.1 g/cm

3

) was similar to that of the beech- and eucalyptus-based

materials with higher density (2.5 - 2.6 g/cm

3

). The fl exure strength measured in

four-point bending by Singh and Salem [Singh, 2002] on mahogany and maple-

based biomorphic Si/SiC composites processed by the same technique is also

included in Figure 11.12b. Maple and mahogany are also hardwoods and their C

templates also present the typical bimodal pore structure. However, no free C was

found in these biomorphic composites and their fl exure strength was in good

agreement with results in C-free low-density biomorphic Si/SiC composites

Search WWH ::

Custom Search