Biomedical Engineering Reference

In-Depth Information

100

95

No cracks

90

85

80

75

70

65

60

Cracks

55

50

0

1

2

3

4

5

distance d (mm)

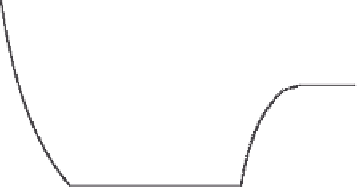

Figure 10.24.

Concentration profi les of graded EPD Al

2

O

3

/ZrO

2

FGM discs. When the ZrO

2

concentration of the core exceeds 25 vol. %, transverse defects are observed. [Anné, 2005a].

(a)

(b)

Figure 10.25.

Typical transverse crack in a symmetrically graded plate with 50 vol. % Al

2

O

3

in

the core (a) and a detailed micrograph of a transverse crack surface. [Anné, 2005a].

the pure Al

2

O

3

layer. The crack opening displacement of most cracks is smaller

than 5

m. From a micrograph of the crack surface (Figure 10.25b), it is clear that

the crack surface is a clear fracture surface and not a sintered surface.

Hillman et al. [Hillman et al., 1996] observed similar defects in symmetrical

laminates with Al

2

O

3

/ZrO

2

layers at the surface and a ZrO

2

central layer. They

found the coexistence of two distinct classes of defects, that is, cracks with a large

opening displacement (

μ

>

30

μ

m) and cracks with a small opening displacement

(

m). It was suggested that defects originated from differential shrinkage

during drying, and that the subsequent densifi cation opened up the defects and

produced cracks with a large opening. The surfaces of this type of crack have

smooth round grains identical to that of a free surface of a densifi ed body. Finer

cracks are thought to be caused by the sintering process. Because the crack

opening in Figure 10.25 is relatively small (

<

2

μ

m), the transverse cracks in the

FGM discs can be assigned to the sintering cycle.

<

5

μ

Search WWH ::

Custom Search