Biomedical Engineering Reference

In-Depth Information

Figure 10.22.

Microstructure of pure Al

2

O

3

sintered for 30 minutes at 1650 °C. [Anné, 2005a].

ZrO

2

100

Al

2

O

3

99

98

97

96

95

Al

2

O

3

/ZrO2 (50/50)

94

93

92

1550 °C

91

90

0

10

20

30

40

50

60

Time (min)

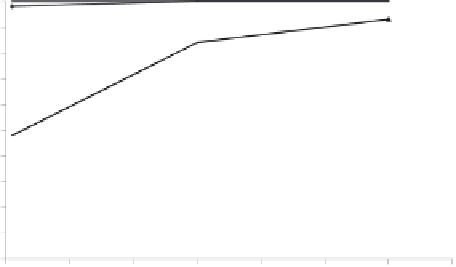

Figure 10.23.

Evolution of the density of Y-ZrO

2

, Al

2

O

3

and 50/50 (vol. %) composite at

1550 °C as a function of time. [Anné, 2005a].

Figure 10.24 gives an overview of the composition profi les of graded Al

2

O

3

/

ZrO

2

discs, leading to transverse cracks after sintering (Figure 10.25). These

cracks are not observed when the Al

2

O

3

content in the core of the graded plate is

≥

75 vol. %, indicating that a too large composition difference between surface

layer and the core gives internal defects. There is no quantitative dependence

found between the inter-crack distance and the composition profi le. Mostly, the

distance between two cracks is a few millimeters, but the number of cracks

increases with the ZrO

2

content in the core of the plates.

Microstructural investigation reveals that these cracks are perpendicular to

the surface (Figure 10.25) and are only present in the ZrO

2

rich core and not in

Search WWH ::

Custom Search