Biomedical Engineering Reference

In-Depth Information

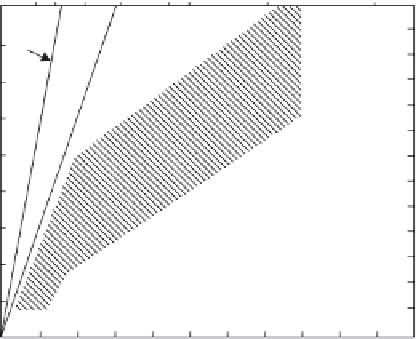

Grain size,

G

(

m)

µ

100 50 20

10

5 4

2

1

90

Slope

=

3.5 MPa

m

1/2

600

Slope

=

2.3 MPa m

1/2

80

500

70

60

400

50

300

40

30

200

Rice, earlier survey

20

100

10

0

0

0

10

20

30

40

50

60

70

80

90

100

(Grain size)

-1/2

,

-1/2

(cm

-1/2

)

G

Figure 10.20.

Strength-grain size relationship for alumina: circles indicate failure where

homogeneous microstructures are involved, squares where exaggerated grains were present.

Symbols with crosses represent specimens ground after hot pressing [Rice, 1997].

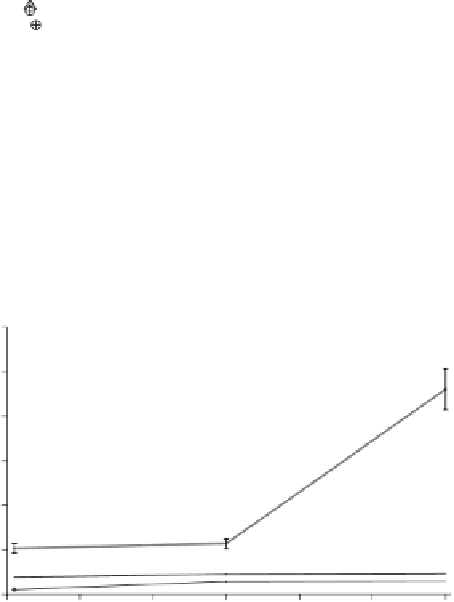

30

25

20

1650°C

15

10

1550°C

5

1450°C

0

0

10

20

30

40

50

60

Time (min)

Figure 10.21.

Al

2

O

3

grain size as a function of the sintering cycle. [Anné, 2005a].

10.7.4 Observation of Processing Defects in FGM Materials

Al

2

O

3

/ZrO

2

FGM discs, made by EPD as described in section 10.5, are sintered

for one hour at 1550 °C. The heating and cooling rate is 3 °C/min. After sintering,

cross-sections are analyzed by scanning electron microscopy (SEM-FEG FEI

XL-30) and the composition profi les are measured by means of EPMA.

Search WWH ::

Custom Search