Biomedical Engineering Reference

In-Depth Information

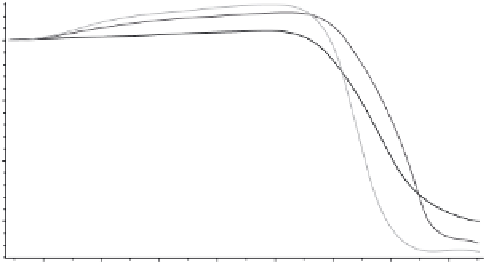

dL/Lo /%

ZrO

2

Al

2

O

3

/ ZrO

2

0

Al

2

0

3

-5

-10

-15

200

400

600

800

1000

1200

1400

1600

Temperature /°C

Figure 10.18.

Dilatometer curves for Al

2

O

3

, ZrO

2

and their 80 vol. % Al

2

O

3

composite.

ZrO

2

particles in the two-phase material are mainly located at the grain bound-

aries and at the grain boundary edges of the alumina grains. However, there are

also some zirconia particles present that are embedded in relatively large alumina

grains. These particles were initially located at grain boundaries and become

intergranular by grain boundary migration of the Al

2

O

3

phase. Figure 10.19

reveals that the average grain size of the alumina grains in the homogeneous

Al

2

O

3

material is larger than that of the two-phase material. In the latter, the

grain growth in the alumina matrix is inhibited by the presence of the secondary

ZrO

2

phase, due to pinning of the Al

2

O

3

grain boundaries, enhancing grain bound-

ary diffusion over grain boundary migration.

10.7.3 Optimization of Grain Size of Al

2

O

3

Composites

Among the mechanical properties that change drastically with a reduction in

grain size is the strength [Helbig, 2000]. The strength-grain size relationship for

hot - pressed Al

2

O

3

is given in Figure 10.20. It is clear that the strength is decreas-

ing with increasing grain size and therefore, the grain size for the Al

2

O

3

is desired

to be smaller than 2

m .

Temperature, soaking time, and heating rate infl uence densifi cation and

coarsening. The infl uence of soaking time and temperature is investigated on

EPD powder compacts of Al

2

O

3

, ZrO

2

and a 50/50 (vol. %) Al

2

O

3

/ZrO

2

compos-

ite. The samples were sintered in air in the tube furnace of a TGA (Cahn TG-171)

at three different temperatures (1450, 1550 and 1650 °C) with three soaking times

(one, 30 and 60 minutes). The specimens were heated at 20 °C/min to 700 °C and

at 10 °C/min to the sintering temperature. For sintering at 1650 °C, heating

between 1600 and 1650 °C was done at 5 °C/min. Cooling was performed at 20 °C/

min

μ

1000 ° C. Afterwards, the samples were cross -

sectioned, polished, and thermally etched for 30 minutes at 1350 °C in air for SEM

>

1000 ° C and 10 ° C/min

<

Search WWH ::

Custom Search