Biomedical Engineering Reference

In-Depth Information

100

A

95

90

B

85

B

80

75

70

A

0

1

2

3

4

5

6

Distance (mm)

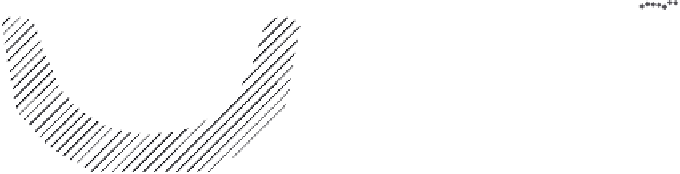

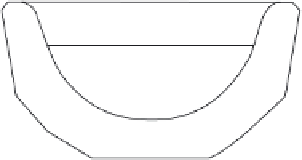

Figure 10.17.

Schematic of a cup insert with indicated measured composition profi le

positions. [Anné, 2005a].

proved to be a severe problem. This is attributed to the strongly variable cross-

section (thickness) of the part. The solution for the drying problem of the ball-

heads was fi nally found by applying a colloidal isopressing technique. In this

developed drying technique, the solvent is pressed out of the green body under

isostatic pressure. For this purpose, the wet ball-head is packed in a plastic bag

and placed in a cold isostatic press. To absorb the solvent, a dry plaster mould is

inserted in the inner hole of the ball-head. Alternatively, solvent absorbing paper

is inserted in the plastic bag around the ball-head. Under the infl uence of pres-

sure (fi ve MPa), a small part of the solvent, contained in the ball-head, is pressed

into the plaster thereby reducing the residual amount of solvent in the ball-head

below the critical level. The isostatic pressure prevents crack formation in the

deposit during drying, allows a rapid solvent removal and increases the green

strength. This drying technique is based on a colloidal forming technique, devel-

oped by Yu et al. [Yu et al., 2001].

Quantitative EPMA analyses are performed on polished cross-sections of

sintered FGM cups (Figure 10.17). The measurements are performed from the

outer to the inner surface of the cup insert. The different positions for profi le

measurements are schematically presented in Figure 10.17. These positions are

chosen because of the wider FGM profi le at position A and the sharpest profi le at

position B.

10.7 SINTERING AND MICROSTRUCTURAL EVALUATION

10.7.1 Introduction

The green EPD powder compacts need to be densifi ed after drying. The powder

compacts are sintered by means of pressureless sintering in air using conventional

heating. Al

2

O

3

and ZrO

2

and their composites are densifi ed by means of solid

state sintering. All densifi cation is achieved through changes in particle shape,

without particle rearrangement or the presence of liquid. Solid state diffusion is

the predominant mass transport. The basic driving force for sintering is a decrease

Search WWH ::

Custom Search